OEM manufacturer custom AC Metric Thread Bite Type Tube Fitting to United Arab Emirates Factory

OEM manufacturer custom AC Metric Thread Bite Type Tube Fitting to United Arab Emirates Factory Detail:

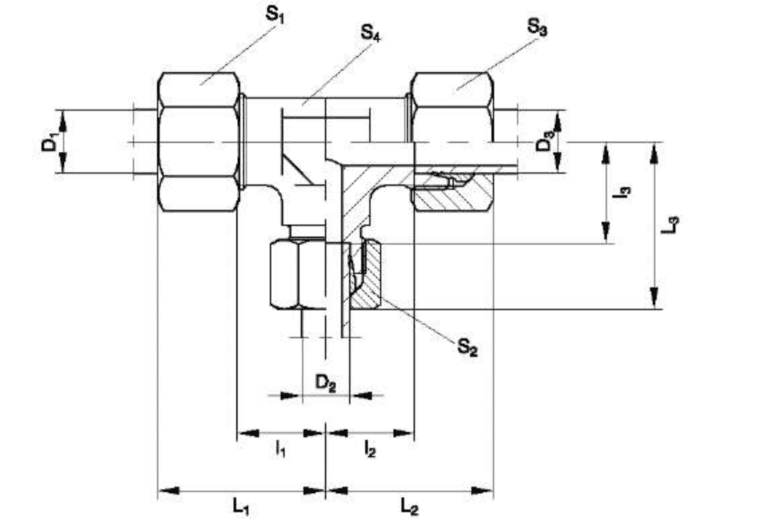

TEE REDUCERS

|

PART NOMBER

|

MPa

|

ØO D.

D1 D2 D3 |

L1 |

L2 |

L3 |

l1 |

l2 |

l3 |

S1 |

S2 |

S3 |

S4 |

bar

|

|||

| AC18-10-10L |

L |

18 | 10 |

10 |

40 | 39 | 39 |

23.5 |

24.0 |

24.0 |

32 | 19 | 19 | 24 |

315 |

|

| AC18-10-18L |

|

18 | 10 |

18 |

40 | 40 | 39 |

23.5 |

23.5 |

24.0 |

32 | 19 | 32 | 24 |

315 |

|

| AC18-12-18L |

|

18 | 12 |

18 |

40 | 40 | 39 |

23.5 |

23.5 |

24.0 |

32 | 22 | 32 | 24 |

315 |

|

| AC18-15-18L |

|

18 | 15 |

18 |

40 | 40 | 39 |

23.5 |

23.5 |

24.0 |

32 | 27 | 32 | 24 |

315 |

|

| AC18-18-10L |

|

18 | 18 |

10 |

40 | 39 | 40 |

23.5 |

24.0 |

23.5 |

32 | 32 | 19 | 24 |

315 |

|

| AC22-10-22L |

|

22 | 10 |

22 |

44 | 44 | 43 |

27.5 |

27.5 |

28.0 |

36 | 19 | 36 | 27 |

160 |

|

| AC22-12-22L |

|

22 | 12 |

22 |

44 | 44 | 43 |

27.5 |

27.5 |

28.0 |

36 | 22 | 36 | 27 |

160 |

|

| AC22-15-15L |

|

22 | 15 |

15 |

44 | 43 | 43 |

27.5 |

28.0 |

28.0 |

36 | 27 | 27 | 27 |

160 |

|

| AC22-15-22L |

|

22 | 15 |

22 |

44 | 44 | 43 |

27.5 |

27.5 |

28.0 |

36 | 27 | 36 | 27 |

160 |

|

| AC22-18-18L |

|

22 | 18 |

18 |

44 | 44 | 44 |

27.5 |

27.5 |

27.5 |

36 | 32 | 32 | 27 |

160 |

|

| AC22-18-22L |

|

22 | 18 |

22 |

44 | 44 | 44 |

27.5 |

27.5 |

27.5 |

36 | 32 | 36 | 27 |

160 |

|

| AC22-22-18L |

|

22 | 22 |

18 |

44 | 44 | 44 |

27.5 |

27.5 |

27.5 |

36 | 36 | 32 | 27 |

160 |

|

| AC28-10-28L |

|

28 | 10 |

28 |

47 | 47 | 46 |

30.5 |

30.5 |

31.0 |

41 | 19 | 41 | 36 |

160 |

|

| AC28-12-28L |

|

28 | 12 |

28 |

47 | 47 | 46 |

30.5 |

30.5 |

31.0 |

41 | 22 | 41 | 36 |

160 |

|

| AC28-15-28L |

|

28 | 15 |

28 |

47 | 47 | 46 |

30.5 |

30.5 |

31.0 |

41 | 27 | 41 | 36 |

160 |

|

| AC28-18-28L |

|

28 | 18 |

28 |

47 | 47 | 47 |

30.5 |

30.5 |

30.5 |

41 | 32 | 41 | 36 |

160 |

|

| AC28-22-22L |

|

28 | 22 |

22 |

47 | 47 | 47 |

30.5 |

30.5 |

30.5 |

41 | 36 | 36 | 36 |

160 |

|

| AC28-22-28L |

|

28 | 22 |

28 |

47 | 47 | 47 |

30.5 |

30.5 |

30.5 |

41 | 36 | 41 | 36 |

160 |

|

METRIC THREAD BITE TYPE

Product detail pictures:

Related Product Guide:

Importance of PVC Fittings

Understanding Hydraulic Hose Fittings

To continuously increase the administration process by virtue of the rule of sincerely, good religion and excellent are the base of company development, we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for OEM manufacturer custom AC Metric Thread Bite Type Tube Fitting to United Arab Emirates Factory, The product will supply to all over the world, such as: Egypt, Ghana, Hyderabad, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Operation of TE 100DG

General Specifications:

100,000 lb. capacity concentrated in 16′

Dimensions: Overall Length: 48′-6″ to 53″

Main Deck Length: 22′ to 26′-6″

Gooseneck: 12′-8″

Width: 8′-6″

King Pin Setting: 16″ to 42″

Swing Clearance 42″ Setting: 79″

Swing Clearance 16″ Setting: 103″

Fifth Wheel Height (unloaded): 50″

Height: 26″

Ground Clearance: 10″

Axle Spacing: 50″

Axle Spacing (50′ long models): 60″

Frame: All high tensile steel. Custom manufactured beams designed for stress loads at a minimum of two times rated capacity. 4 full size ultra high tensile steel main beams.

Platform: 2″ oak decking attached to every crossmember with torx head screws. Center boards are left loose for outrigger use. Excavator cut out, open floor. Wheel bolsters between axles only (no wheel covers). Front loading ramps.

Gooseneck: Air activated lock. PTO operated hydraulics. Hydraulic neck support arm.

Note: All hydraulics are set up to operate at 3,000 PSI.

Axles: (3) 25,000 lb. with oil seal hubs.

Brakes: S Cam air activated 16-1/2″ x 7″ with automatic slack adjusters.

Wheels: (12) 8.25 x 22.5 disk wheels.

Tires: (12) 255/70R x 22.5 radials.

Suspension: Air ride with air dump valve.

“D” Rings: (14) 7 per side of deck bed. Including bolsters.

Outriggers: On 2′ centers.

Electrical: Sealed beam light system with mid-ship turn signal.

Paint: Trailer sandblasted, primed and painted one coat 2-part polyurethane.

Warranty: Limited 5 Year Pro-Rated Major Structural Warranty (USA and Canada ONLY).

Options: Many options available.

Please call 1-800-232-5682 or e-mail sales@traileze.com for more information on options.

Due to the constant improvements in our products, the designs, materials and specifications are subject to change without notice.

Instructional video showing how to solder stainless to stainless, using https://MuggyWeld.com SSF-6 56% Silver Solder.

Please read all instructions prior to use at: https://www.muggyweld.com/wp-content/uploads/2017/04/SSF-6-instructions.pdf

For more videos and information, or to order, visit https://MuggyWeld.com

International customers, please order at: https://www.ebay.com/usr/muggyweld

_________________

Please visit https://www.aws.org/technical/facts/ prior to using Muggy Weld products, and adhere to all AWS welding safety guidelines. Further product safety information is available at https://muggyweld.com/safety-guidelines.

Muggy Weld LLC shall not be liable for any loss, injury, claim, liability, or damage of any kind resulting in any way from (a) your use of this Site, (b) any services or products obtained from this Site, (c) any errors in or omissions from this Site, (d) the unavailability or interruption of this Site or any features thereof, (e) any content contained on this Site.

MSDS sheets available with purchase from MuggyWeld.com, upon request.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!