Hot-selling attractive price 87643-Interlock Hose Fitting for Danish Manufacturer

Hot-selling attractive price 87643-Interlock Hose Fitting for Danish Manufacturer Detail:

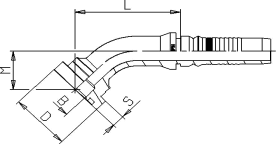

45° SAE FLANGE 6000 P.S.I.

|

PART NUMBER |

HOSE

|

FLANGE

|

B mm |

L mm |

D mm |

M

mm |

S

mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| H876C0 – 10 – 12 | 16 | 5/8″ | 10 | 3/4″ | 18 | 61,9 | 41,3 | 28 | 8,76 |

| H876C0 – 12 – 12 | 20 | 3/4″ | 12 | 3/4″ | 18 | 69,9 | 41,3 | 30,5 | 8,76 |

| H876C0 – 12 – 16 | 20 | 3/4″ | 12 | 1″ | 23 | 72,6 | 47,6 | 33,3 | 9,53 |

| H876C0 – 16 – 16 | 25 | 1″ | 16 | 1″ | 23 | 85,5 | 47,6 | 37,5 | 9,53 |

| H876C0 – 16 – 20 | 25 | 1″ | 16 | 1.1/4″ | 30 | 87,9 | 54 | 40,1 | 10,29 |

| H876C0 – 20 – 20 | 32 | 1.1/4″ | 20 | 1.1/4″ | 30 | 100,2 | 54 | 43 | 10,29 |

| H876C0 – 20 – 24 | 32 | 1.1/4″ | 20 | 1.1/2″ | 36 | 105,1 | 63,5 | 47,9 | 12,57 |

| H876C0 – 24 – 24 | 40 | 1.1/2″ | 24 | 1.1/2″ | 36 | 113 | 63,5 | 51,8 | 12,57 |

| H876C0 – 24 – 32 | 40 | 1.1/2″ | 24 | 2″ | 48 | 120,4 | 79,4 | 59,2 | 12,57 |

| H876C0 – 32 – 32 | 50 | 2″ | 32 | 2″ | 48 | 150,8 | 79,4 | 67,8 | 12,57 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

How to Replace a Hydraulic Hose Fitting

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Hot-selling attractive price 87643-Interlock Hose Fitting for Danish Manufacturer, The product will supply to all over the world, such as: Paraguay, Grenada, Orlando, We are fully aware of our customer's needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Best Drill Bits For Metal, Stainless Steel and Hardened Steel. Having a hard time finding the correct drill bit for the kind of steel you need to drill. You have found the right video to watch. I will explain it all from HSS (high speed steel), Cobalt Drill Bit, Carbide Drill Bit, Massonry Drill Bit, Locksmith Drill Bit.

The Ultimate Guide To Drill Bits, Cobalt, HSS, Carbide, How to chose the best drill bit for Stainless steel, Hardened steel,

Please Click The Subscribe Button Below!

Comments and questions are encouraged but please be respectful.

www.tricountylocksmithservice.com

This is The Ultimate Guide To Drill Bits. Putting HSS (High Speed Steel), Cobalt, Carbide tipped and solid Carbide drill bits to the test. Yes It’s long but Compared to the Year + it took to gather the information it’s not that bad. So Sit Back and learn or keep wasting your money on junk, trash bits that keep breaking and not drilling through what you want them to.

RHC – Rockwell Hardness C

HSS Drill Bits – Work well up to the 50ish RHC

Drill – Mild steel, Some tool steel, Some Spring Steel

No Drill – Hard Plate, Anti Drill Plate, 404c Stainless Steel

Pro – Good in Hand Drills and most drilling applications

Con – Has limitations in hardened steels

Cobalt – Works up to 58ish RHC

Drill – Mild Steel, Some Spring Steel, Some Tool Steel

No Drill – Hard Plate, Anti Drill Plate, 440C Stainless Steel

Pro – Good for hand drills and most drilling applications

Con – Has limits with hardened steel

Carbide Tipped – Will drill almost any steel, Hard, Stainless or Mild.

Pro – Drills all steel

Con- Blunt tip requires extreme pressure to produce cuttings. Drill bit is hard to start on all steels.

Diamond Coated Drill Bit – Cuts on most steels(Not Hard Plate) just not for long.

Pro – Will Drill most steels (Not Hard Plate)

Con – Cutting stops quickly after diamond grit has warn off, Then behaves like HSS bit

Solid Carbide Drill Bit – Cuts all steels.

Pro – Sharpened points wont “walk” like carbide tipped bit. Cuts all steel

Con – Sharp tip and fine edges can chip easily and ruin drill bit. Not for hand drills. Expensive!

For more information go to www.Tricountylocksmithservice.com

Drill bits purchased from www.drillbitwarehouse.com Discount Code – lockman1

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.