Factory directly provided 10511 Swaged Hose Fiting to El Salvador Factories

Factory directly provided 10511 Swaged Hose Fiting to El Salvador Factories Detail:

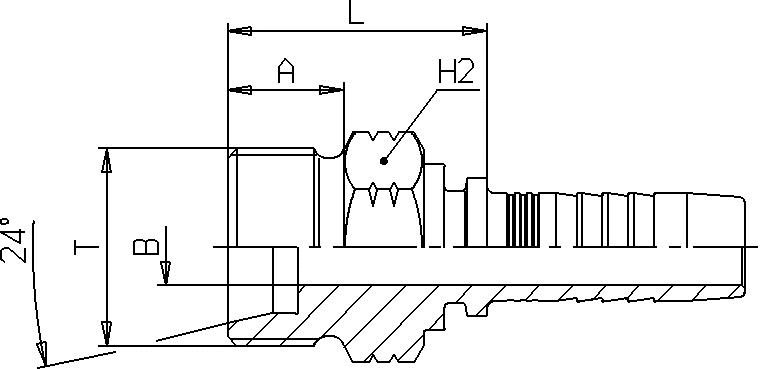

METRIC MALE 24° CONE SEAT HEAVY TYPE DIN 3861 ( CES )

|

PART NUMBER |

HOSE

|

THREAD T |

PIPE |

B mm |

L mm |

A mm |

H1 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S105A0 – 03 – 16 | 5 | 3/16″ | 03 | M16x1,5 | 8 | 5,5 | 25 | 12 | 17 |

| S105A0 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 8 | 5,5 | 25,5 | 12 | 17 |

| S105A0 – 04 – 18 | 6 | 1/4″ | 04 | M18x1,5 | 10 | 5,5 | 26,5 | 12 | 19 |

| S105A0 – 05 – 20 | 8 | 5/16″ | 05 | M20x1,5 | 12 | 7 | 29 | 12 | 22 |

| S105A0 – 05 – 24 | 8 | 5/16″ | 05 | M24x1,5 | 16 | 9,5 | 30,5 | 14 | 24 |

| S105A0 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 10 | 7 | 27,6 | 12 | 19 |

| S105A0 – 06 – 20 | 10 | 3/8″ | 06 | M20x1,5 | 12 | 7 | 29,6 | 12 | 22 |

| S105A0 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 14 | 8 | 31,6 | 14 | 22 |

| S105A0 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 14 | 9,3 | 31,9 | 14 | 22 |

| S105A0 – 08 – 24 | 12 | 1/2″ | 08 | M24x1,5 | 16 | 9,3 | 31,3 | 14 | 24 |

| S105A0 – 10 – 30 | 16 | 5/8″ | 10 | M30x2 | 20 | 15 | 35,8 | 16 | 30 |

| S105A0 – 12 – 30 | 20 | 3/4″ | 12 | M30x2 | 20 | 15 | 36,5 | 16 | 30 |

| S105A0 – 12 – 36 | 20 | 3/4″ | 12 | M36x2 | 25 | 19,5 | 40 | 18 | 36 |

| S105A0 – 16 – 36 | 25 | 1″ | 16 | M36x2 | 25 | 19,5 | 40,8 | 18 | 36 |

| S105A0 – 16 – 42 | 25 | 1″ | 16 | M42x2 | 30 | 25 | 43,8 | 20 | 46 |

| S105A0 – 20 – 52 | 32 | 1.1/4″ | 20 | M52x2 | 38 | 30 | 49,5 | 22 | 55 |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Importance of PVC Fittings

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Factory directly provided 10511 Swaged Hose Fiting to El Salvador Factories, The product will supply to all over the world, such as: New York, Brunei, Honduras, Our company regards reasonable prices, high quality,efficient production time and good after-sales service as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

Piping,Welding,Non Destructive Examination-NDT

How To Get Weight of Pipe in Tons Using Formula

Common Piping Angles and their Solutions,Known and Unknown Angles and Angle Chart,Solving Rolling Offsets,mitered Pipe Cuts,Multipiece Mitered turns, “Y” Layout,90 deg. Saddle on (tees) Standard Weight Pipe,Pipe Circumference Divided into Equal Parts,90 deg.on (tees) extra Strong Pipe,90 deg. Eccentric Pipe Intersections, 45 deg. laterals,Concentric and Eccentric Supports on 90 deg. Long Radius Elbow,3 Types,Angle between Bolt Holes of Flanges, Pipe template layout,orange Peel head layout,Concentric Reducer Layout,Eccentric Reducer Layout,laying out Bolt Holes in Flanges,laying Out Ordinate Lines and lengths,Tank coil layout,Angle Iron Miter Cuts and Brackets,Special Offsets and Solutions,Slip or Spectacle Blind Data,Centers of Eccentric reducers and Eccentric Flanges,Centers of 15 deg.,221/2,30 & 60 deg. Butt Weld Elbows from 90 deg. Long Radius Elbows,Pipe Thread,Dimension of Weldolet on Pipe, Dimension of Socket Weld & Screwed Fittings, Dimension of Flanges Cast Steel Valves,Dimension of Flanges Cast Steel Fittings,Commercial Pipe Sizes & Welding Fittings,General Dimension of Welding Fittings,General Dimension of Forged Steel Flanges,Bolt,Gasket & Ring Joint Number Charts,Wrench Sizes,Drill Sizes for Pipe Taps,& Tap Drill Size Charts,Bolt Charts for Orifice Type Flange,Outside & Inside Diameter of Pipe& Flange Bores,Comparison Chart for Packing & gasket materials,Hand Signal for boom Operated Equipment,Hand Signal for Overhead & gantry Cranes,Useful Information,Pipe Expansion,Pipe Bends,Circle,Inches&Feet Converted to millimeters,Conversion Constant,Decimal Equivalents,Fractions& millimeters,Safe Loads,for Wire and Manila Rope Charts,Decimal of a Foot,minutes converted to Decimals of a Degree and trigonometric formulas,Pipe& Water Weight Per Line Foot &Feet head of Water to PSI,Wire bending,Symbols,Computation.

50 gallon salt water coral reef fish tank filtration system change and installation. New client within the gta GTA Toronto Canada with a running fluval studio 900 50 gallon salt water coral reef fish tank. Running with fluval canister filter with seachem phosguard, biomedia and fluval charcoal. I will be taking out the fluval canister filtration system and be installing a sump filtration system. With submersible return pump roughly 10x the water trim over rate. Along with protein skimmer Tunze Comline doc 9004 model. Either hang on the back of display tank or submersibale in sump. First step was to examine the tank set up and plan over the design that works best for my client.

To start, right off the bat I noticed the drain pipe level in the display tank was too low. Sitting roughly 10 inches lower than water level. This is the correct way to have the drain pipe if you are running the fluval canister filtration system. As the canister is closed and leak proof, this is why the drain pipe can be located at the height in the tank. I’m referring this drain pipe as a “drain pipe”, but can also be considered as the intake for the pump that is running the canister filter. And then once filtered via the filter. The filter pump will now pump that clean water back into the tank. Via the “return pipe”

So therefore the reason of my explanation is to point out that I needed to extend the drain pipe in the display tank to the correct height so the water level in the display tank will be consistent and always at the same level and at the preferred viewing level.

So for me to raise this drain pipe to the correct level I tried to see what Pvc sizes would fit. Looked like 1/2″-3/4″ Pvc would fit. I tried and did not fit. After scattering through all my plumbing that I had at the job location. Finally realized that nothing o had would fit or work.

Long story short! We ordered an attachment pipe from fluval that perfectly slips right over the drain that is currently there, that we need to raise to the correct height. This pipe we ordered from fluval does not get glued or threaded. The pipe fitting as special rubber O ring that is located in the inner side of the pipe and slips over the pre existing drain pipe and has a water tight seal with just the pipe fitting and internal O rings. We tested this drain for leaks below in the cabinet before we proceed to the next step. Removal of the canister filter. Close valve to canister filter to close. And disconnect power supply. Remove filters and hoses. Install new Pvc fitting and barb hose fittings and claps. Installed the drain and return to new sump filtration along with ball valves. To control flow rate to sump and from pump to tank. Connect and install sump pump, via Pvc and hose and valve. Install acrylic sump roughly 20x20x16 3 chamber sump. With drain being the first with live rock and second being the refugium with live sand and chato malcro algae. And finally the return pump chamber with the return pump and protein skimmer. As well as the heater is submersed in sump as well. Once plumbing and sump installed. We are now ready to add more water to the system and then turn on the power to the pump to start cycle. Adjust drain height in display tank to roughly 1″ below top of the tank rim.

Once the system was running, and topped up the water in the system to the desired height we perform a power outage test.

Disconnect power supply to pump and observe the back syphon via the pump return line. Watch the sump as the water back flows into the sump and make sure that the sump does not over flow.

This test must be performed for safety and proper installation test.

Thanks for watching

Stay tuned Links

Youtube channel LEOPAZZO link https://www.youtube.com/user/Leopazzoinyourmouth/featured

Salt water fish tanks made easy Facebook group

https://m.facebook.com/groups/241799872643193?ref=bookmark

Reef tank addiction Facebook page

https://m.facebook.com/ReeftoReef?ref=bookmark

Lenny V Leopazzo Facebook personal link https://m.facebook.com/lennyvolpe.moderntouch?ref=bookmark

New web site by LEOPAZZO

Coralreefadddictionfamily.com

Facebook group please join and share radio station live streaming

HOT T DOT RADIO 416-905 https://m.facebook.com/groups/671549709622629?ref=bookmark

HOT T DOT RADIO 416-905 Facebook Page please visit the page and like and share and post if you like music https://m.facebook.com/profile.php?id=798617620232842&ref=bookmark

LEOPAZZO aquariums on USTREAM live streaming special events https://ustre.am/:3Zi32

Hot T Dot Radio on USTREAM Toronto music artist https://ustre.am/:40Rof

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.