Quality Inspection for 12611 Swaged Hose Fiting for Nigeria Manufacturer

Quality Inspection for 12611 Swaged Hose Fiting for Nigeria Manufacturer Detail:

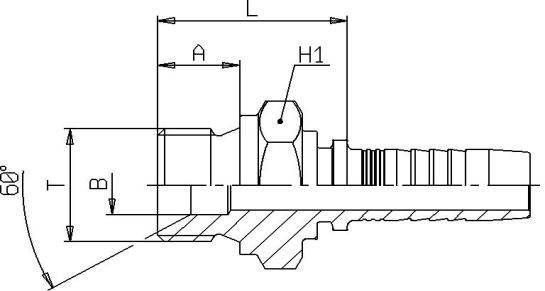

BSP MALE PARALLEL 60° CONE SEAT

| PART NUMBER | HOSE | THREADT | Bmm | Lmm | Amm | H1mm | ||

| DN | In | SIZE | ||||||

| S126A0 - 03 - 02 | 5 | 3/16″ | 03 | 1/8″ - 28 | 3,5 | 20,6 | 8 | 14 |

| S126A0 - 04 - 02 | 6 | 1/4″ | 04 | 1/8″ - 28 | 3,5 | 20,5 | 8 | 14 |

| S126A0 - 04 - 04 | 6 | 1/4″ | 04 | 1/4″ - 19 | 5 | 25,5 | 11 | 19 |

| S126A0 - 04 - 06 | 6 | 1/4″ | 04 | 3/8″ - 19 | 8 | 27 | 12 | 22 |

| S126A0 - 05 - 06 | 8 | 5/16″ | 05 | 3/8″ - 19 | 8 | 27,5 | 12 | 22 |

| S126A0 - 06 - 06 | 10 | 3/8″ | 06 | 3/8″ - 19 | 8 | 28,1 | 12 | 22 |

| S126A0 - 06 - 08 | 10 | 3/8″ | 06 | 1/2″ - 14 | 11 | 32,1 | 14 | 27 |

| S126A0 - 08 - 06 | 12 | 1/2″ | 08 | 3/8″ - 19 | 8 | 28,3 | 12 | 22 |

| S126A0 - 08 - 08 | 12 | 1/2″ | 08 | 1/2″ - 14 | 11 | 32,3 | 14 | 27 |

| S126A0 - 08 - 10 | 12 | 1/2″ | 08 | 5/8″ - 14 | 14,5 | 36,3 | 16 | 30 |

| S126A0 - 08 - 12 | 12 | 1/2″ | 08 | 3/4″ - 14 | 16,5 | 36,3 | 16 | 32 |

| S126A0 - 10 - 10 | 16 | 5/8″ | 10 | 5/8″ - 14 | 14,5 | 34,3 | 16 | 30 |

| S126A0 - 10 - 12 | 16 | 5/8″ | 10 | 3/4″ - 14 | 16,5 | 36,3 | 16 | 32 |

| S126A0 - 12 - 12 | 20 | 3/4″ | 12 | 3/4″ - 14 | 16,5 | 37,5 | 16 | 32 |

| S126A0 - 12 - 16 | 20 | 3/4″ | 12 | 1″ - 11 | 22 | 41 | 19 | 41 |

| S126A0 - 16 - 16 | 25 | 1″ | 16 | 1″ - 11 | 22 | 41,8 | 19 | 41 |

| S126A0 - 16 - 20 | 25 | 1″ | 16 | 1.1/4″ - 11 | 28,5 | 46,3 | 20 | 50 |

| S126A0 - 20 - 20 | 32 | 1.1/4″ | 20 | 1.1/4″ - 11 | 28,5 | 47 | 20 | 50 |

| S126A0 - 24 - 24 | 40 | 1.1/2″ | 24 | 1.1/2″ - 11 | 33,5 | 52,5 | 22 | 55 |

| S126A0 - 32 - 32 | 50 | 2″ | 32 | 2″ - 11 | 46 | 62,9 | 25 | 70 |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Importance of PVC Fittings

Sticking towards the theory of Super Good quality, Satisfactory service ,We are striving to become a superb business enterprise partner of you for Quality Inspection for 12611 Swaged Hose Fiting for Nigeria Manufacturer, The product will supply to all over the world, such as: Montpellier, Nigeria, azerbaijan, Adhering to the principle of Enterprising and Truth-Seeking, Preciseness and Unity, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

Gentleman asked me if I could make some manifold flanges for his Franklin O-805-2 Drone engine.this video shows me making both the flanges and the fixture plate for those flanges.

Materials:

• new shower head

• new shower arm pipe (optional)

• teflon tape

• Pipe wrench or lock jaw pliers

• rag

• Wall Flange

Steps:

1. Clear the area and cover the side of the tub with a rag.

Begin by clearing out the tub or shower area, and cover the side of the tub with a rag so the tools do not damage the finish.

2. Unscrew and remove the shower head and shower head arm-pipe.

Most showerheads will unscrew by hand. If not, use a pipe wrench or lock-jaw pliers. If you are also changing the shower head arm-pipe, unscrew that as well.

3. Install new shower head arm-pipe (optional).

If you are installing a new shower head arm-pipe, start by wrapping the threads that will go into the wall with Teflon tape. This makes for a leak-free connection. Then install the pipe by hand threading it into the wall outlet. Make sure the pipe faces down and is tight.

4. Install wall flange.

Slide the wall flange (sold separately from the shower head) over the arm-pipe. If desired, you can secure this to the wall with a small amount of caulking behind the flange.

5. Install new shower head.

Most new shower heads come with washers to prevent leaks, be sure to install these as the manufacturer recommends. Hand thread the showerhead onto the arm-pipe, and tighten with a pipe wrench or lock-jaw pliers. Use a rag to protect the shower head from damage from the wrench.

6. Install wand hose (optional).

If your new shower head has a hand wand option, install the wand hose, making sure to install a washer if required. Hand tighten.

7. Turn on water and check for leaks.

Run water and check for leaks at any connection. If leaks are found, turn off the water, tighten connections and check again.

Optional Items:

• Caulking

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.