Massive Selection for 12611 Swaged Hose Fiting for Swansea Factories

Massive Selection for 12611 Swaged Hose Fiting for Swansea Factories Detail:

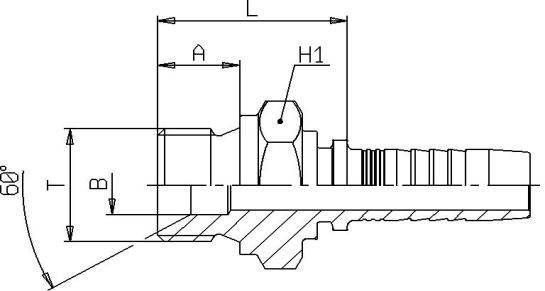

BSP MALE PARALLEL 60° CONE SEAT

| PART NUMBER | HOSE | THREADT | Bmm | Lmm | Amm | H1mm | ||

| DN | In | SIZE | ||||||

| S126A0 - 03 - 02 | 5 | 3/16″ | 03 | 1/8″ - 28 | 3,5 | 20,6 | 8 | 14 |

| S126A0 - 04 - 02 | 6 | 1/4″ | 04 | 1/8″ - 28 | 3,5 | 20,5 | 8 | 14 |

| S126A0 - 04 - 04 | 6 | 1/4″ | 04 | 1/4″ - 19 | 5 | 25,5 | 11 | 19 |

| S126A0 - 04 - 06 | 6 | 1/4″ | 04 | 3/8″ - 19 | 8 | 27 | 12 | 22 |

| S126A0 - 05 - 06 | 8 | 5/16″ | 05 | 3/8″ - 19 | 8 | 27,5 | 12 | 22 |

| S126A0 - 06 - 06 | 10 | 3/8″ | 06 | 3/8″ - 19 | 8 | 28,1 | 12 | 22 |

| S126A0 - 06 - 08 | 10 | 3/8″ | 06 | 1/2″ - 14 | 11 | 32,1 | 14 | 27 |

| S126A0 - 08 - 06 | 12 | 1/2″ | 08 | 3/8″ - 19 | 8 | 28,3 | 12 | 22 |

| S126A0 - 08 - 08 | 12 | 1/2″ | 08 | 1/2″ - 14 | 11 | 32,3 | 14 | 27 |

| S126A0 - 08 - 10 | 12 | 1/2″ | 08 | 5/8″ - 14 | 14,5 | 36,3 | 16 | 30 |

| S126A0 - 08 - 12 | 12 | 1/2″ | 08 | 3/4″ - 14 | 16,5 | 36,3 | 16 | 32 |

| S126A0 - 10 - 10 | 16 | 5/8″ | 10 | 5/8″ - 14 | 14,5 | 34,3 | 16 | 30 |

| S126A0 - 10 - 12 | 16 | 5/8″ | 10 | 3/4″ - 14 | 16,5 | 36,3 | 16 | 32 |

| S126A0 - 12 - 12 | 20 | 3/4″ | 12 | 3/4″ - 14 | 16,5 | 37,5 | 16 | 32 |

| S126A0 - 12 - 16 | 20 | 3/4″ | 12 | 1″ - 11 | 22 | 41 | 19 | 41 |

| S126A0 - 16 - 16 | 25 | 1″ | 16 | 1″ - 11 | 22 | 41,8 | 19 | 41 |

| S126A0 - 16 - 20 | 25 | 1″ | 16 | 1.1/4″ - 11 | 28,5 | 46,3 | 20 | 50 |

| S126A0 - 20 - 20 | 32 | 1.1/4″ | 20 | 1.1/4″ - 11 | 28,5 | 47 | 20 | 50 |

| S126A0 - 24 - 24 | 40 | 1.1/2″ | 24 | 1.1/2″ - 11 | 33,5 | 52,5 | 22 | 55 |

| S126A0 - 32 - 32 | 50 | 2″ | 32 | 2″ - 11 | 46 | 62,9 | 25 | 70 |

Product detail pictures:

Related Product Guide:

Importance of PVC Fittings

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

abide by the contract, conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Massive Selection for 12611 Swaged Hose Fiting for Swansea Factories, The product will supply to all over the world, such as: Costa rica, Australia, Amsterdam, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

Vacuum Booster with vacuum pump brake booster conversion to Hydro-Boost from SPE∑D Manufacturing.

Ford GM and Dodge Diesel Truck Hydro-Boost Brake Booster Conversion / Replacements.

the booster port adapters should already be screwed into your booster, the 90 degree stainless hoses go into them. We try and shrink wrap the reusable fittings to the hoses that they belong to so that you know where they go (there are a lot of different arrangements which makes it hard to do an end all be all print instruction guide, but we will be including that soon). Simply putting the fittings with the hoses they belong to often makes them impossible to get wrong since the big 3 automakers tend to make all power steering hoses with a big fitting and small fitting to each side (so it would be hard for a guy on the assembly line to get hundreds of them wrong by accident).

GM and Dodge units normally come with banjo fittings into the booster, but for Fords, 99 times out of 100 It goes:

-Separate the master cylinder from the booster, there is no fluid connection here (only mechanical), so just remove the two – or sometimes three or four – nuts that hold it down to the booster. If you are reusing the master, than just move it off to the side and don’t crack open the brake line fittings. If you are installing a mew master, than take the brake lines off and set the master off to the side with the ports facing up so that the fluid doesn’t leak out onto your bench or floor. Be careful because brake fluid will eat paint, so don’t get it on the fender, and keep water nearby to poor on it in case it does.

-There are normally 4 bolts holding the vacuum booster onto the firewall, they are normally located under the dash and tend to be inconvenient to get to. The connection that holds the Vacuum booster input rod to the brake pedal will also be found while under the dash. It can be a clevis yoke, heim joint, or standard pedal rod end with a rounded or flat tip that is held in with one of a few types of clips. Detach this clip, then pull the booster out from the engine bay.

-1st 90 degree stainless hose – Smaller port on the Pump out to the larger port on the booster (accumulator side, the one with only one fitting),

-2nd 90 degree stainless hose – Smaller Large Port on the Booster to the larger port on the steering box,

-smaller port on the steering box out to the larger (in) port on the reservoir for the pump with the rubber hose (cut it to the length you need, slip it onto the tube or barb and clamp it down.

then the hydro-boost return (barb fitting on the side of the booster from the barb to the return line from the box return to the pump. Cut the box to pump line and fit the included T into it with the straight shot going from box to pump. Slip the HB return onto the perpendicular barb

-Then tighten down all fittings and clamps at each end of each hose.

-Brake bleeding is the same as normal. Bench bleeding normally leads to brake fluid dribbling out on the fender since so many master cylinders don’t have check valves. ‘Gravity bleeding’ is great in these cases because no air is introduced deep down in your system unless you crack open the bleeder screws at the calipers – which there is no reason to do unless you are changing your calipers at the same time. On a gravity bleed, you just tighten down the brake line fittings into the master, then back them up, cracking them open allows the small bit of air to work its way up as the fluid goes down from the master into the lines. When fluid begins to drip at the port, your brakes are bled.

If you kept your stock master cylinder, than there would have been no need to crack open the brake lines, so no bleeding of the brakes would have been necessary. You’re good to go once the booster is bolted down to the firewall, master bolted down to the booster, and the booster rod is clipped onto the brake pedal.

-Fill the p/s reservoir and turn the wheels back and forth to cycle the fluid through the system. Then turn the engine over without starting it to further cycle it through. Keep topping off the reservoir, then run the car, and test drive when the level does not go down anymore. Dextron and/or Mercon ATF (not straight ATF, but Mercon/Dextron), can be added to the system to cut down on the foaming that happens when doing such surgery on the power steering system.

There is a good truck installation, which is a conversion from vacuum to Hydro-Boost, in another video that we have on Youtube. Just search ’8 lug hydroboost’, or click on this link to watch it, https://www.youtube.com/watch?v=FgC_sQmHlvs.

Sponsored by SPE∑D Manufacturing (Sweeting Performance Engineering Marketing & Design) Now if doctors could just do for cancer what we do for brakes, we’d be set. Performance Air-Hydraulic Systems, Electric-Hydraulic Brake Systems & Bosch Hydro-Boost™ Kits https://www.powerbrakeservice.net

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.