Top Suppliers BC-W Metric Thread Bite Type Tube Fitting for Angola Factories

Top Suppliers BC-W Metric Thread Bite Type Tube Fitting for Angola Factories Detail:

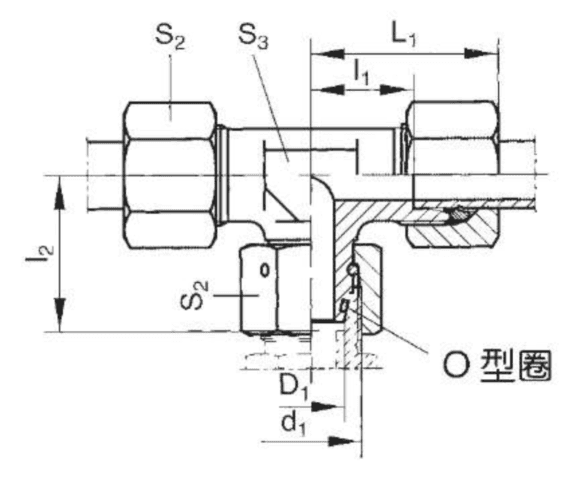

BRANCH TEE FITTINGS WITH SWIVEL NUT

|

PART NOMBER

|

MPa

|

TUBE O D.

|

d1 |

L1 |

l1 |

l2 |

S2 |

S3 |

O型圈 |

bar

|

| BC-06L | L | 06 | M12x1.5 | 27 | 12.0 | 26.0 | 14 | 12 | OR4.5×1.5 | 315 |

| BC-08L | 08 | M14x1.55 | 29 | 14.0 | 27.5 | 17 | 12 | OR6.5×1.5 | 315 | |

| BC-10L | 10 | M16x1.55 | 30 | 15.0 | 29.0 | 19 | 14 | OR8x1.5 | 315 | |

| BC-12L | 12 | M18x1.5 | 32 | 17.0 | 29.5 | 22 | 17 | OR10x1.5 | 315 | |

| BC-15L | 15 | M22x1.5 | 36 | 21.0 | 32.5 | 27 | 19 | OR12x2 | 315 | |

| BC-18L | 18 | M26x1.5 | 40 | 23.5 | 35.5 | 32 | 24 | OR15x2 | 315 | |

| BC-22L | 22 | M 30×2 | 44 | 27.5 | 38.5 | 36 | 27 | OR20x2 | 160 | |

| BC-28L | 28 | M 36×2 | 47 | 30.5 | 41.5 | 41 | 36 | OR26x2 | 160 | |

| BC-35L | 35 | M 45×2 | 56 | 34.5 | 51.0 | 50 | 41 | OR32x2.5 | 160 | |

| BC-42L | 42 | M 52×2 | 63 | 40.0 | 56.0 | 60 | 50 | OR38x2.5 | 160 | |

| BC-06S | S | 06 | M14x1.5 | 31 | 16.0 | 27.0 | 17 | 12 | OR4.5×1.5 | 630 |

| BC-08S | 08 | M16x1.5 | 32 | 17.0 | 27.5 | 19 | 14 | OR6.5×1.5 | 630 | |

| BC-10S | 10 | M18x1.5 | 34 | 17.5 | 30.0 | 22 | 17 | OR8x1.5 | 630 | |

| BC-12S | 12 | M20x1.5 | 38 | 21.5 | 31.0 | 24 | 17 | OR10x1.5 | 630 | |

| BC-14S | 14 | M22x1.5 | 40 | 22.0 | 35.0 | 27 | 19 | OR11x2 | 630 | |

| BC-16S | 16 | M24x1.5 | 43 | 24.5 | 36.5 | 30 | 24 | OR13x2 | 400 | |

| BC-20S | 20 | M 30×2 | 48 | 26.5 | 44.5 | 36 | 27 | OR16.3×2.4 | 400 | |

| BC-25S | 25 | M 36×2 | 54 | 30.0 | 50.0 | 46 | 36 | OR20.3×2.4 | 400 | |

| BC-30S | 30 | M 42×2 | 62 | 35.5 | 55.0 | 50 | 41 | OR25.3×2.4 | 400 | |

| BC-38S | 38 | M 52×2 | 72 | 41.0 | 63.0 | 60 | 50 | OR33.3×2.4 | 315 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

How to Replace a Hydraulic Hose Fitting

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for Top Suppliers BC-W Metric Thread Bite Type Tube Fitting for Angola Factories, The product will supply to all over the world, such as: Macedonia, Guatemala, Slovak Republic, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

Tips for lubing the front hub assembly of four-by-four Super Duty Ford Trucks.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.