Short Lead Time for 10411 Swaged Hose Fiting for Thailand Manufacturers

Short Lead Time for 10411 Swaged Hose Fiting for Thailand Manufacturers Detail:

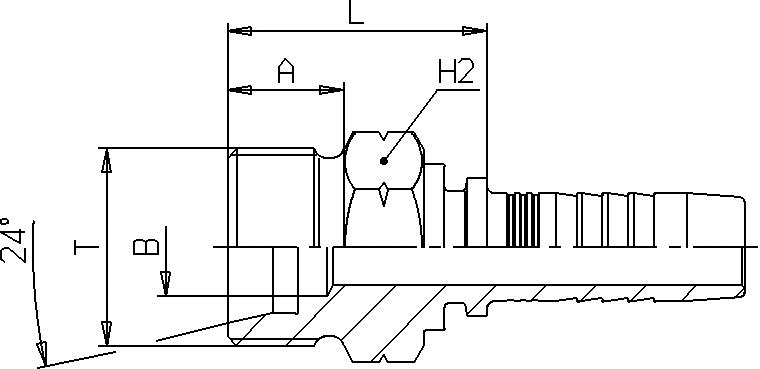

METRIC MALE 24° CONE SEAT LIGHT TYPE DIN 3861 ( CEL )

|

PART NUMBER |

HOSE

|

THREAD T

|

PIPE |

B mm |

L mm |

A mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S104A0 – 03 – 12 | 5 | 3/16″ | 03 | M12x1,5 | 6 | 3 | 21,1 | 10 | 14 |

| S104A0 – 04 – 12 | 6 | 1/4″ | 04 | M12x1,5 | 6 | 4 | 21,5 | 10 | 14 |

| S104A0 – 04 – 14 | 6 | 1/4″ | 04 | M14x1,5 | 8 | 4 | 21,5 | 10 | 14 |

| S104A0 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 10 | 7 | 23,5 | 11 | 17 |

| S104A0 – 04 – 18 | 6 | 1/4″ | 04 | M18x1,5 | 12 | 9,5 | 23,5 | 11 | 19 |

| S104A0 – 05 – 16 | 8 | 5/16″ | 05 | M16x1,5 | 10 | 7 | 24 | 11 | 17 |

| S104A0 – 05 – 18 | 8 | 5/16″ | 05 | M18x1,5 | 12 | 9,5 | 24 | 11 | 19 |

| S104A0 – 06 – 16 | 10 | 3/8″ | 06 | M16x1,5 | 10 | 7 | 24,1 | 11 | 17 |

| S104A0 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 12 | 9,5 | 24,6 | 11 | 19 |

| S104A0 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 15 | 10 | 25,6 | 12 | 22 |

| S104A0 – 08 – 18 | 12 | 1/2″ | 08 | M18x1,5 | 12 | 9,3 | 24,8 | 11 | 19 |

| S104A0 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 15 | 10 | 25,8 | 12 | 22 |

| S104A0 – 08 – 26 | 12 | 1/2″ | 08 | M26x1,5 | 18 | 12 | 26,3 | 12 | 27 |

| S104A0 – 10 – 26 | 16 | 5/8″ | 10 | M26x1,5 | 18 | 12 | 26,3 | 12 | 27 |

| S104A0 – 12 – 30 | 20 | 3/4″ | 12 | M30x2 | 22 | 15 | 29,5 | 14 | 30 |

| S104A0 – 16 – 36 | 25 | 1″ | 16 | M36x2 | 28 | 19,5 | 31,8 | 14 | 36 |

| S104A0 – 20 – 45 | 32 | 1.1/4″ | 20 | M45x2 | 35 | 26 | 39,5 | 16 | 46 |

| S104A0 – 24 – 52 | 40 | 1.1/2″ | 24 | M52x2 | 42 | 32 | 40,5 | 16 | 55 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Short Lead Time for 10411 Swaged Hose Fiting for Thailand Manufacturers, The product will supply to all over the world, such as: Sierra Leone, United Arab emirates, Guinea, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

https://www.4x4offroads.com/dana-44-locking-hubs.html

In this video I am showing you how to replace Dana 44 locking hubs with some refurbished ones.

Starting with getting the worn out Warn hub. Loosening up the screws with a hex key or allen wrench. Once the screws are loose you can get the cap off.

On the inside you can see the locking mechanism. There are two snap rings holding it. The smaller sits on the axle itself and you get it off with a small screwdriver. The outer one is a little bit more tricky to get off, but with the same screwdriver and perhaps another to assist you should be able to get it off.

Now the unit is loose and you can use two of the screws to help getting it out.

I am using a refurbished locking unit I found on eBay.

You start with the big spring and then the outer ring that fits in the grooves on the outside of the hub. It has got a castle that locks into the axle ring. You may have to turn the axle slightly to have the rings lock together.

Next comes a controlling ring with two ears that are used to push the outer ring further into the hub to free the lock. Outside of that is the ring with holes to fasten the cap.

In this case the ring is rather tight fitting so I am gently using a hammer to get it into place. It must get within the groove for the outer snapring.

Finally the snap rings are snapped into place. First the outer one and you must be sure it sits well in its place. Same with the axle snap ring it must sit nicely in its groove.

I am marking the place where the screw must sit.

The cap must be in the FREE position and you must position the “ears” of the controlling ring against the highest area of the cap – so it pushes the lock to the FREE position.

Fitting the screws in the correct place and make sure the cap sits tightly in the correct place and the screws are fastened.

Test out the locking hub by turning to the LOCK position and back again.

If the truck is jacked up you can turn the hub to confirm the axle turns with the wheel when it is in the LOCK position.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.