Reliable Supplier 20511-T Swaged Hose Fiting for The Swiss Importers

Reliable Supplier 20511-T Swaged Hose Fiting for The Swiss Importers Detail:

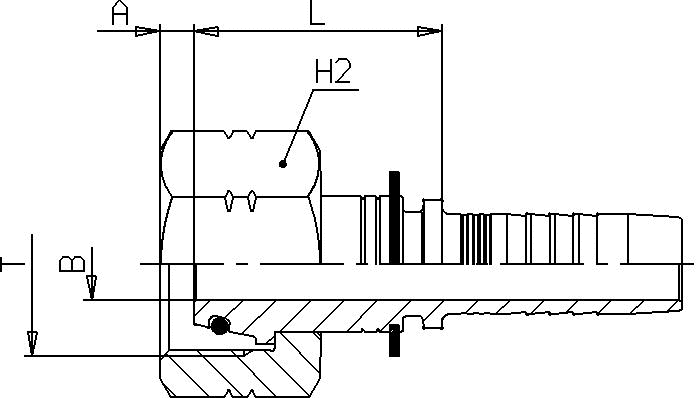

O’RING METRIC FEMALE 24° CONE HEAVY TYPE DIN 3865

|

PART NUMBER |

HOSE

|

THREAD T |

PIPE |

B mm |

L mm |

A mm |

|

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

|

| S205A1 – 03 – 16 | 5 | 3/16″ | 03 | M16x1,5 | 8 | 3 | 26,1 | 4,4 | 19 | |

| S205A1 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 8 | 4 | 26,6 | 4,4 | 19 | |

| S205A1 – 04 – 18 | 6 | 1/4″ | 04 | M18x1,5 | 10 | 4 | 28 | 3 | 22 | |

| S205A1 – 05 – 20 | 8 | 5/16″ | 05 | M20x1,5 | 12 | 5,5 | 28,1 | 2,5 | 24 | |

| S205A1 – 06 – 20 | 10 | 3/8″ | 06 | M20x1,5 | 12 | 7 | 28,6 | 2,5 | 24 | |

| S205A1 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 14 | 7 | 32,6 | 3,5 | 27 | |

| S205A1 – 08 – 24 | 12 | 1/2″ | 08 | M24x1,5 | 16 | 9,3 | 32,3 | 4,5 | 30 | |

| S205A1 – 10 – 30 | 16 | 5/8″ | 10 | M30x2 | 20 | 12 | 37,3 | 4 | 36 | |

| S205A1 – 12 – 36 | 20 | 3/4″ | 12 | M36x2 | 25 | 15 | 40,5 | 4,5 | 46 | |

| S205A1 – 16 – 42 | 25 | 1″ | 16 | M42x2 | 30 | 19,5 | 43,8 | 6,3 | 50 | |

| S205A1 – 20 – 52 | 32 | 1.1/4″ | 20 | M52x2 | 38 | 26 | 49,5 | 8 | 60 | |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Reliable Supplier 20511-T Swaged Hose Fiting for The Swiss Importers, The product will supply to all over the world, such as: Nigeria, Gambia, Czech republic, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

The RCBS Case Prep center can be fitted with a Lee Case Trimmer Cutter that has been slightly modified (see below) and a Lee Case Length Gage. This adds trimming to the list of case preparation functions and allows the RCBS Case Prep Center to do almost everything that needs to be done to a piece of brass. Tumble clean the brass, process the brass through the multiple stages on the RCBS Case Prep Center and it’s ready to be reloaded with a primer, powder and bullet. Approximately 150 brass cases can be processed in an hour, including trimming to length, chamfering inside and outside the case neck and preparing the primer pocket. The Hornady Primer Pocket Reamer Cutter Head reams the primer pocket to the correct diameter, including the removal of any military primer pocket crimp, and chamfers the entrance to the primer pocket to facilitate the entry of the new primer into the primer pocket. Redding makes a very nice primer pocket uniformer that will ream the primer pocket to the proper diameter and also cut the primer pocket to the correct depth. The Redding Primer Pocket Uniformer is a bit pricey at $30, but carbide cutting tools are expensive. They also last a long time.

NOTE ABOUT THE MODIFIED CUTTER:

I drilled and tapped one cutter for me and it was a little hard but not a problem for a sharp high speed steel drill on my little mill-drill. I did one for a friend and it was very difficult. The steel cutter was very hard. I think Lee makes the cutters from a tool steel that they subsequently induction heat treat, and I think my initial cutter wasn’t properly heat treated which probably explained why it dulled so quickly cutting brass.

I eventually used a cobalt drill, low RPM and a lot of pressure to drill the hardened steel. I used a much larger center drill to start the hole because the #29 tap drill for 8-32 would walk long before drilling. The center drill is much shorter and fatter and therefore stiffer. Once I had a divot started, I drilled the tap hole. I almost broke a tap, so I drilled a larger hole for much less thread engagement and tapped that larger hole. I think the thread engagement was so little that I epoxied the stud in place?

I now recommend getting a scrap chunk of aluminum or plastic, drill a #29 hole all the way through the center, use that as the pilot hole to drill a much larger hole part way through that’s just barely large enough for the cutter body and epoxy it in place after tapping the #29 hole on the base and screwing in a #8-32 screw from the inside so the threads stick out the bottom by 3/8″ or so.

https://www.midwayusa.com/viewproduct/?productnumber=617234

https://www.midwayusa.com/viewproduct/?productnumber=253550

https://www.midwayusa.com/viewproduct/?productnumber=729748

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.