Professional High Quality 10411 Swaged Hose Fiting for South Korea Manufacturer

Professional High Quality 10411 Swaged Hose Fiting for South Korea Manufacturer Detail:

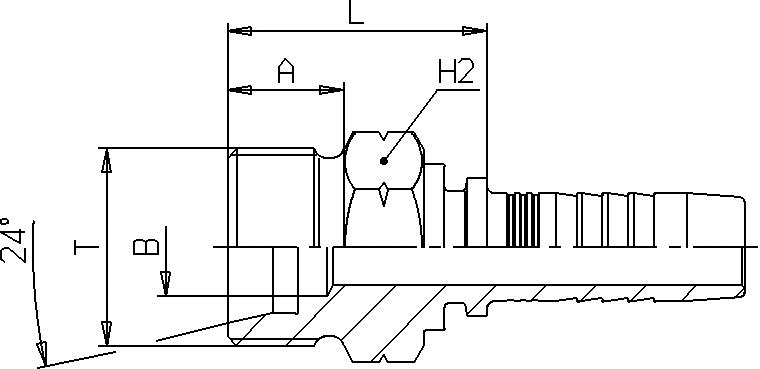

METRIC MALE 24° CONE SEAT LIGHT TYPE DIN 3861 ( CEL )

|

PART NUMBER |

HOSE

|

THREAD T

|

PIPE |

B mm |

L mm |

A mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S104A0 – 03 – 12 | 5 | 3/16″ | 03 | M12x1,5 | 6 | 3 | 21,1 | 10 | 14 |

| S104A0 – 04 – 12 | 6 | 1/4″ | 04 | M12x1,5 | 6 | 4 | 21,5 | 10 | 14 |

| S104A0 – 04 – 14 | 6 | 1/4″ | 04 | M14x1,5 | 8 | 4 | 21,5 | 10 | 14 |

| S104A0 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 10 | 7 | 23,5 | 11 | 17 |

| S104A0 – 04 – 18 | 6 | 1/4″ | 04 | M18x1,5 | 12 | 9,5 | 23,5 | 11 | 19 |

| S104A0 – 05 – 16 | 8 | 5/16″ | 05 | M16x1,5 | 10 | 7 | 24 | 11 | 17 |

| S104A0 – 05 – 18 | 8 | 5/16″ | 05 | M18x1,5 | 12 | 9,5 | 24 | 11 | 19 |

| S104A0 – 06 – 16 | 10 | 3/8″ | 06 | M16x1,5 | 10 | 7 | 24,1 | 11 | 17 |

| S104A0 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 12 | 9,5 | 24,6 | 11 | 19 |

| S104A0 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 15 | 10 | 25,6 | 12 | 22 |

| S104A0 – 08 – 18 | 12 | 1/2″ | 08 | M18x1,5 | 12 | 9,3 | 24,8 | 11 | 19 |

| S104A0 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 15 | 10 | 25,8 | 12 | 22 |

| S104A0 – 08 – 26 | 12 | 1/2″ | 08 | M26x1,5 | 18 | 12 | 26,3 | 12 | 27 |

| S104A0 – 10 – 26 | 16 | 5/8″ | 10 | M26x1,5 | 18 | 12 | 26,3 | 12 | 27 |

| S104A0 – 12 – 30 | 20 | 3/4″ | 12 | M30x2 | 22 | 15 | 29,5 | 14 | 30 |

| S104A0 – 16 – 36 | 25 | 1″ | 16 | M36x2 | 28 | 19,5 | 31,8 | 14 | 36 |

| S104A0 – 20 – 45 | 32 | 1.1/4″ | 20 | M45x2 | 35 | 26 | 39,5 | 16 | 46 |

| S104A0 – 24 – 52 | 40 | 1.1/2″ | 24 | M52x2 | 42 | 32 | 40,5 | 16 | 55 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

How to Replace a Hydraulic Hose Fitting

Persisting in High quality, Prompt Delivery, Aggressive Price, now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Professional High Quality 10411 Swaged Hose Fiting for South Korea Manufacturer, The product will supply to all over the world, such as: Latvia, Curacao, Cyprus, Wide selection and fast delivery to suit your needs! Our philosophy: Good quality, great service, keep improving. We've been looking forward that more and more oversea friends join in our family for further development near the future!

World’s first leak-tight double block and bleed isolation of a high pressure CO2 pipeline system.

STATS Group were contracted by Kinder Morgan to provide a pipeline hot tapping and plugging operation on a high pressure 30” Carbon Dioxide pipeline operating at 2,140 psi.

The purpose of this project, which took place as part of a larger initiative to convert a non-piggable pipeline into a piggable pipeline, was to install full bore inline valves and retrofit pigging launchers and receivers into the pipeline system. The installation of a 24” bypass pipeline around the isolated section allowed continuous production and avoided system downtime during maintenance activities.

This intervention operation took place on a 500 mile 30” CO2 pipeline that operates from source fields in southwestern Colorado to Denver City, delivering product primarily used for enhanced oil recovery. The pipeline is currently undergoing significant upgrades to facilitate a transition to a piggable pipeline for ease of ongoing inspection and maintenance.

Pipeline isolation was provided with the installation of STATS patented BISEP™. The BISEP™ provides fail-safe double block and bleed isolation deployed through a single full bore hot tap penetration. The leak-tight isolation provided, dramatically increases safety over traditional line-stop technology and doesn’t require any additional hot tap vents or bleed ports. The BISEP™ contains dual energised seals and the annulus zero-energy zone proves and monitors the seal integrity before and during intervention work.

STATS have carried out isolations at five sites along the CO2 pipeline operating at around 2,000 psi and have completed in excess of 190 days of individual BISEP™ isolation, whilst avoiding system downtime during critical maintenance activities.

For more information visit – https://www.statsgroup.com/

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.