One of Hottest for 1CB-Metric Thread Bite Type Tube Fitting to Czech republic Manufacturer

One of Hottest for 1CB-Metric Thread Bite Type Tube Fitting to Czech republic Manufacturer Detail:

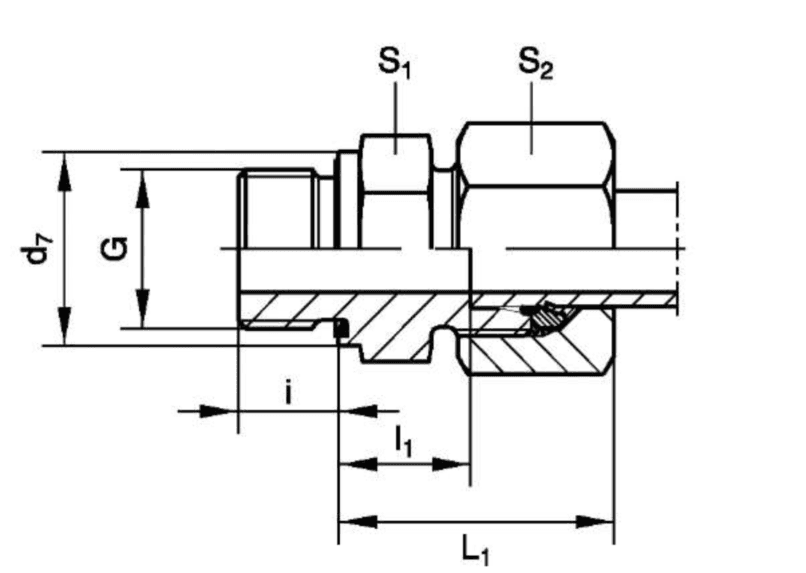

SP THREAD STUD ENDS WITH ED-RING SEALING

| PART NOMBER | Mpa | TUBE O D. | G | L1 | l1 | i | S2 | S1 | d7 | bar |

| 1CG-06L-02ED | L | 06 | G1/8A | 23 | 8.5 | 8 | 14 | 14 | 14 | 315 |

| 1CG-06L-04ED | 06 | G1/4A | 25 | 10.0 | 12 | 14 | 19 | 19 | 315 | |

| 1CG-06L-06ED | 06 | G3/8A | 26 | 11.5 | 12 | 14 | 22 | 22 | 315 | |

| 1CG-06L-08ED | 06 | G1/2A | 27 | 12.0 | 14 | 14 | 27 | 27 | 315 | |

| 1CG-08L-04ED | 08 | G1/4A | 25 | 10.0 | 12 | 17 | 19 | 19 | 315 | |

| 1CG-08L-06ED | 08 | G3/8A | 26 | 11.5 | 12 | 17 | 22 | 22 | 315 | |

| 1CG-08L-08ED | 08 | G1/2A | 27 | 12.0 | 14 | 17 | 27 | 27 | 315 | |

| 1CG-10L-04ED | 10 | G1/4A | 26 | 11.0 | 12 | 19 | 19 | 19 | 315 | |

| 1CG-10L-06ED | 10 | G3/8A | 27 | 12.5 | 12 | 19 | 22 | 22 | 315 | |

| 1CG-10L-08ED | 10 | G1/2A | 28 | 13.0 | 14 | 19 | 27 | 27 | 315 | |

| 1CG-12L-04ED | 12 | G1/4A | 27 | 12.0 | 12 | 22 | 19 | 19 | 315 | |

| 1CG-12L-06ED | 12 | G3/8A | 27 | 12.5 | 12 | 22 | 22 | 22 | 315 | |

| 1CG-12L-08ED | 12 | G1/2A | 28 | 13.0 | 14 | 22 | 27 | 27 | 315 | |

| 1CG-12L-12ED | 12 | G3/4A | 29 | 14.0 | 16 | 22 | 32 | 32 | 315 | |

| 1CG-15L-06ED | 15 | G3/8A | 29 | 13.5 | 12 | 27 | 24 | 22 | 315 | |

| 1CG-15L-08ED | 15 | G1/2A | 29 | 14.0 | 14 | 27 | 27 | 27 | 315 | |

| 1CG-15L-12ED | 15 | G3/4A | 30 | 15.0 | 16 | 27 | 32 | 32 | 315 | |

| 1CG-18L-06ED | 18 | G3/8A | 30 | 14.0 | 12 | 32 | 27 | 22 | 315 | |

| 1CG-18L-08ED | 18 | G1/2A | 31 | 14.5 | 14 | 32 | 27 | 27 | 315 | |

| 1CG-18L-12ED | 18 | G3/4A | 31 | 14.5 | 16 | 32 | 32 | 32 | 315 | |

| 1CG-22L-08ED | 22 | G1/2A | 33 | 16.5 | 14 | 36 | 32 | 27 | 160 | |

| 1CG-22L-12ED | 22 | G3/4A | 33 | 16.5 | 16 | 36 | 32 | 32 | 160 | |

| 1CG-22L-16ED | 22 | G1A | 34 | 17.5 | 18 | 36 | 41 | 40 | 160 | |

| 1CG-28L-12ED | 28 | G3/4A | 34 | 17.5 | 16 | 41 | 41 | 32 | 160 | |

| 1CG-28L-16ED | 28 | G1A | 34 | 17.5 | 18 | 41 | 41 | 40 | 160 | |

| 1CG-28L-20ED | 28 | G1-1/4A | 35 | 18.5 | 20 | 41 | 50 | 50 | 160 | |

| 1CG-35L-16ED | 35 | G1A | 39 | 17.5 | 18 | 50 | 46 | 40 | 160 | |

| 1CG-35L-20ED | 35 | G1-1/4A | 39 | 17.5 | 20 | 50 | 50 | 50 | 160 | |

| 1CG-35L-24ED | 35 | G1-1/2A | 41 | 19.5 | 22 | 50 | 55 | 55 | 160 | |

| 1CG-42L-16ED | 42 | G1A | 42 | 19.0 | 18 | 60 | 55 | 40 | 160 | |

| 1CG-42L-20ED | 42 | G1-1/4A | 42 | 19.0 | 20 | 60 | 55 | 50 | 160 | |

| 1CG-42L-24ED | 42 | G1-1/2A | 42 | 19.0 | 22 | 60 | 55 | 55 | 160 |

Product detail pictures:

Related Product Guide:

How to Replace a Hydraulic Hose Fitting

Understanding Hydraulic Hose Fittings

With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for One of Hottest for 1CB-Metric Thread Bite Type Tube Fitting to Czech republic Manufacturer, The product will supply to all over the world, such as: Morocco, Romania, Muscat, Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.