OEM/ODM Manufacturer 87693-Interlock Hose Fitting to Johor Factory

OEM/ODM Manufacturer 87693-Interlock Hose Fitting to Johor Factory Detail:

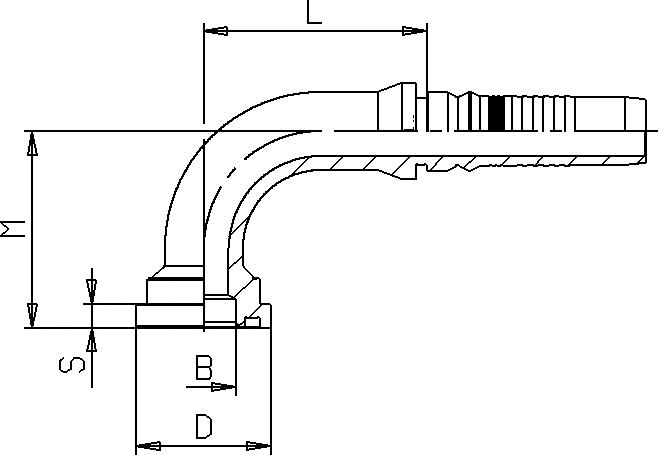

90° SAE FLANGE 6000 P.S.I.

|

PART NUMBER |

HOSE

|

FLANGE

|

B mm |

L mm |

D mm |

M

mm |

S

mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| H876B0 – 10 – 12 | 16 | 5/8″ | 10 | 3/4″ | 18 | 50,9 | 41,3 | 55,3 | 8,76 |

| H876B0 – 12 – 12 | 20 | 3/4″ | 12 | 3/4″ | 18 | 60,1 | 41,3 | 62,5 | 8,76 |

| H876B0 – 12 – 16 | 20 | 3/4″ | 12 | 1″ | 23 | 60,1 | 47,6 | 66,5 | 9,53 |

| H876B0 – 16 – 16 | 25 | 1″ | 16 | 1″ | 23 | 74,2 | 47,6 | 77,5 | 9,53 |

| H876B0 – 16 – 20 | 25 | 1″ | 16 | 1.1/4″ | 30 | 74,2 | 54 | 81 | 10,29 |

| H876B0 – 20 – 20 | 32 | 1.1/4″ | 20 | 1.1/4″ | 30 | 90,2 | 54 | 90,4 | 10,29 |

| H876B0 – 20 – 24 | 32 | 1.1/4″ | 20 | 1.1/2″ | 36 | 90,2 | 63,5 | 97,4 | 12,57 |

| H876B0 – 24 – 24 | 40 | 1.1/2″ | 24 | 1.1/2″ | 36 | 100,6 | 63,5 | 108,9 | 12,57 |

| H876B0 – 24 – 32 | 40 | 1.1/2″ | 24 | 2″ | 48 | 100,6 | 79,4 | 120,4 | 12,57 |

| H876B0 – 32 – 32 | 50 | 2″ | 32 | 2″ | 48 | 135,7 | 79,4 | 144,7 | 12,57 |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Importance of PVC Fittings

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we've got earned an fantastic reputation among our buyers across the globe for OEM/ODM Manufacturer 87693-Interlock Hose Fitting to Johor Factory, The product will supply to all over the world, such as: Belgium, El Salvador, United Arab Emirates, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

For the next video in this series, please click here: https://www.monkeysee.com/play/18526-building-a-greenhouse-constructing-walls-and-door-frame

To find the list of materials for this project, please click here: https://monkeysee.com/video_clips/18523-building-a-greenhouse-shopping-for-materials

Pusat Hydraulic Hose Fitting Terlengkap Samarinda, Kaltim, untuk pelayanan consigment, assy retail, partai atau eceran mendukung industri tambang batu bara, oil and gas serta industri automotive. https://www.sriwijayateknikutama.com/penyedia-hydraulic-hose-fitting-terlengkap/

Managers are visionary, they have the idea of mutual benefits, continuous improvement and innovation, we have a pleasant conversation and Cooperation.