OEM manufacturer custom 22691-W Swaged Hose Fiting to kazakhstan Factories

OEM manufacturer custom 22691-W Swaged Hose Fiting to kazakhstan Factories Detail:

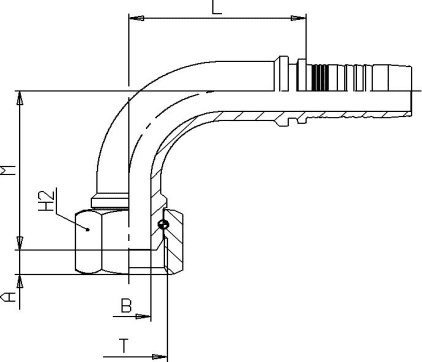

90° BSP FEMALE 60° CONE

|

PART NUMBER |

HOSE

|

THREAD T |

B mm |

L mm |

A mm |

M mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S226B2 – 04 -02 | 6 | 1/4″ | 04 | 1/8″ – 28 | 3 | 28 | 4,4 | 32,4 | 14 |

| S226B2 – 05 -04 | 8 | 5/16 | 05 | 1/4″ – 1 | 4 | 31 | 5.2 | 33.5 | 10 |

| S226B2 – 06 – 04 | 10 | 3/8″ | 06 | 1/4″ – 1 | 4 | 34 | 5.2 | 37 | 19 |

| S226B2 – 08 -06 | 12 | 1/2″ | 08 | 3/8″ – 19 | 7 | 40 | 6 | 43 | 22 |

| S226B2 – 10 -10 | 16 | 5/8″ | 10 | 5/8″ – 14 | 12 | 48 | 9,7 | 52,2 | 30 |

| S226B2 – 12–12 | 20 | 3/4″ | 12 | 3/4″ – 14 | 15 | 55 | 9 | 62 | 32 |

| S226B2 – 16–16 | 25 | 1″ | 16 | 1″ – 11 | 19,5 | 73 | 10,5 | 77,3 | 38 |

| S226B2 – 16 – 20OR | 25 | 1″ | 16 | 1.1/4″ – 11 | 26 | 73 | 10,1 | 84.3 | 50 |

| S226B2 – 20 – 20OR | 32 | 1.1/4″ | 20 | 1.1/4″ – 11 | 26 | 89.8 | 10,1 | 93 | 50 |

| S226B2 – 20 – 24OR | 32 | 1.1/4″ | 20 | 1.1/2″ – 11 | 32 | 89.8 | 12,5 | 94 | 55 |

| S226B2 – 24 – 24OR | 40 | 1.1/2″ | 24 | 1.1/2″ – 11 | 32 | 103 | 12,5 | 106 | 55 |

| S226B2 – 24 – 32OR | 40 | 1.1/2″ | 24 | 2″ – 11 | 32 | 103 | 16,1 | 110.4 | 70 |

| S226B2 – 32 – 32OR | 50 | 2″ | 32 | 2″ – 11 | 42 | 126 | 16,1 | 124 | 70 |

Product detail pictures:

Related Product Guide:

How to Replace a Hydraulic Hose Fitting

Things to Know About Pipe Fitting Works

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for OEM manufacturer custom 22691-W Swaged Hose Fiting to kazakhstan Factories, The product will supply to all over the world, such as: Mauritania, Hungary, British, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Advanced Drainage Systems, Inc (ADS) and Hancor, Inc provides Innovative Drainage and Water Conservation Solutions using Corrugated High Density Polyethylene HDPE Pipe. Preview HDPE Pipe Trench Preparation.

A properly designed steam system is extremely important. Clean, dry steam through your steam distribution network maximizes the quality of steam, and protects all related components thus keeping costs and maintenance to a minimum.

Principles of Operation of the Pressure Reducing Valve: – Normal positions before start-up are with the main valve closed and the pilot valve held open by spring force or air pressure. Entering steam passes through the pilot valve into the main diaphragm chamber and also out through the control orifice. As flow through the pilot valve exceeds flow through the orifice, control pressure increases in the diaphragm chamber and opens the main valve. As steam flows through the main valve, the increase in downstream pressure feeds back through the pressure sensing line to the underside of the pressure diaphragm. When the force below that diaphragm balances the compression force of the spring above it, the pilot valve throttles. The control pressure maintained in the main diaphragm chamber positions the main valve to deliver just enough steam for the desired delivery pressure. Adjustment of the spring or air pressure above the pressure diaphragm changes the downstream pressure set point. When steam is no longer required, the sensing line pressure increases closing the pressure pilot and the control pressure bleeds back through the control orifice. This allows the main valve to hold the desired reduced pressure, and it may close tight for a dead-end shutoff.

Operation of the Spirax Sarco Model 25PRV Pressure Reducing Valve

0:0:24 No Flow Conditions

0:0:27 Steam Flow Begins

0:0:29 Progresses Toward Equilibrium

0:0:35 Attains Set Point

0:0:43 Increased Downstream Load

0:0:56 Elevated Setpoint

0:1:09 Downstream Shutoff

0:1:19 The Spirax Sarco Model 25PRV Features

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.