Manufacturing Companies for 70011 Swaged Hose Fiting to Paris Factories

Manufacturing Companies for 70011 Swaged Hose Fiting to Paris Factories Detail:

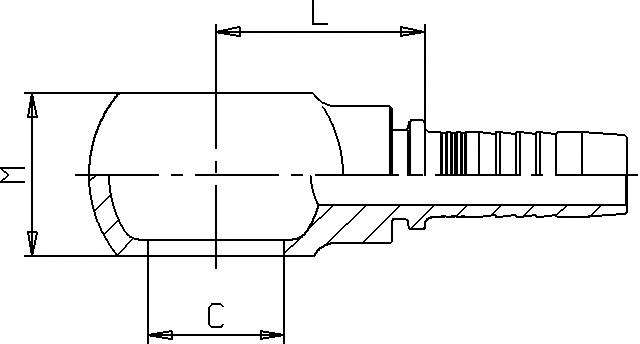

METRIC BANJO

|

PART NUMBER |

HOSE |

BOLT THREAD |

|

L mm |

C mm |

M mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

| S700A0 – 04 – 12 | 6 | 1/4″ | 04 | M12x1,5 | 22,3 | 12,1 | 12 | |

| S700A0 – 04 – 14 | 6 | 1/4″ | 04 | M14x1,5 | 24,3 | 14,1 | 14 | |

| S700A0 – 05 – 14 | 8 | 5/16″ | 05 | M14x1,5 | 24,3 | 14,1 | 14 | |

| S700A0 – 06 – 16 | 10 | 3/8″ | 06 | M16x1,5 | 26,8 | 16,1 | 16 | |

| S700A0 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 28,8 | 18,1 | 20 | |

| S700A0 – 08 – 18 | 12 | 1/2″ | 08 | M18x1,5 | 29,1 | 18,1 | 20 | |

| S700A0 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 32,1 | 22,1 | 25 | |

| S700A0 – 10 – 22 | 16 | 5/8″ | 10 | M22x1,5 | 32,2 | 22,1 | 25 | |

| S700A0 – 12 – 26 | 20 | 3/4″ | 12 | M26x1,5 | 38,1 | 26,1 | 30 | |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

How to Replace a Hydraulic Hose Fitting

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science plus the theory of quality the basic, have faith in the main and management the advanced for Manufacturing Companies for 70011 Swaged Hose Fiting to Paris Factories, The product will supply to all over the world, such as: Vancouver, Montreal, Sao Paulo, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

This DIY Wood Floating Shelf project is a great one for anyone looking to get into woodworking and for the more advanced, alike. It’s very budget friendly, does not take long to make, and they add a nice touch to any wall. Learn how to make your wood floating shelves!

For more info, project photos, and downloadable plans check out:

https://www.diypete.com/FloatingShelves

Download Plans: https://gumroad.com/l/FloatingShelves

Vinegar and Steel Wool Tutorial Video: https://www.youtube.com/watch?v=tqFnBcKUdhA

*Note that these are affiliate links, meaning that when you buy something that is recommended below, it helps support the Channel. Thanks in advance!

*Tools Needed

Circular Saw – https://amzn.to/1OxNa7k

Table Saw – https://amzn.to/1X7Eje5

Drill – https://amzn.to/1OxMfnt

Kreg Jig – https://amzn.to/1X7Bd9H

Nail Gun – https://amzn.to/1R0RUDB

Clamps – https://amzn.to/1LwiDEs

Cut All of the Wood Pieces

We’ll start this project by marking and making cuts for all of the different pieces for the wood floating shelf. It basically consists of the 2×4 wood frame that screws into the studs in your wall and also the cedar picket shelf box that slides onto the frame. Take a look at the cut list in the free plans for dimensions and guidance. Sand the boards, once they’re cut to size.

Start Assembly, Making the Frame First

Once you have all of your pieces, we’ll make the 2×4 wood frame that’ll screw into the wall. Kreg Jig (pocket hole joinery) the short boards onto the longer board. Also screw in 3” wood screws from the opposite side, for more security. This frame will be completely hidden on the inside of the cedar shelf box, so once it’s made there is no need to finish this. You can leave it all rough.

Assemble the Cedar Box Shelf

Then we’ll put together the cedar box that will slide over the 2×4 frame, becoming the main shelf and the most visible part of this project. Dry fit all of the pieces to make sure your cuts were accurate, then add wood glue to the joints. Nail everything together with 1 ¼” nails and then let the glue dry.

Sand, Finish, and Let Cure

Sand the cedar box down to at least 220 grit with your orbital sander. The finishing process that I did for this project was the steel wool and vinegar solution/stain. Let your solution work its magic for a while and once to the desired color, seal it all up with a water-based spray polyurethane. The water-based sealer ensures that you won’t change the effect, patina, and color of the steel wool and vinegar solution.

Install the 2×4 Frame and the Cedar Shelf

Once the finishing process is done and everything has dried to the manufacturer’s recommended time, we can install it! We’ll first find the studs in the wall, should be about 16” apart. Then we’ll screw the 2×4 frame into the wall with 2 3” wood screws for each connection to the stud. Slide the cedar box shelf on and you’re done!

*Note: If you’re wanting a more secure shelf (maybe the kids could pull the shelf off of the frame) you can simply screw the shelf onto the 2×4 frame from the underside or topside.

Enjoy!

You’ve done the work, now reap the benefits of your DIY Wood Floating Shelf or Shelves, in my case. Add what you want to them and share this project with your friends. Thanks for following along and be sure to check out the free, downloadable plans.

–

Looking for more DIY videos? Be sure to check out our channel and subscribe for updates! We post a weekly tutorial every Thursday.

Looking for woodworking, concrete working, and other DIY projects plans to follow? You can download plans for free at https://gumroad.com/DIYPETE

Facebook: https://facebook.com/DiyProjectsWithPete

Instagram: https://instagram.com/diypete

DIYPETE.com

1627 W Main Street Suite 182

Bozeman, Montana 59715

Disc Brake Adapter Sprocket to Hub MBrebel.com

Will fit on most aluminum DISC hub wheels with spokes.

Inner ring is 53mm, DISC rotor surface diameter needs to be under 53mm.

6 outer holes are 10mm diameter.

Weight: 2.6oz

Outer Diameter: 106mm, 4.17inches

Center Hole Diameter Bore: 34.5mm, 1.36in

Inner stepped in Ring Cup Diameter goes against rotor surface: 53mm, 2inches

Outer step Diameter: 59.03mm, 2.32inches

For use with sprockets that fit on sprocket adapters.

The sprocket flat head holes need to be filed or drilled to 10mm holes.

And 3 single speed chainring bolts can be used to join the sprocket and Disc Brake Adapter.

See final sample picture. Sprocket and chainring bolts not included.

Adapter can be flipped for wider tires or motor alignment, although the adapter is more secure with cup around DISC hub rotor surface.

MBRebel sprockets for sprocket adapters can be used on either side of the adapter.

Will fit on the following wheels. (Not Included)

Rear Disc Single Speed Freewheel Wheel 26 X 2.125 12 Gauge Spoke Chrome Rim 38mm Wide Alloy Hub, SKU: 10136

Rear Disc Freewheel Wheel 24 X 2.125 11 Gauge Spoke Chrome Rim 38mm Wide, SKU: 10050

Alloy Double Wall 36 HOLE 11 Gauge SS 26″inch 42mm Wide Rim Black Rear Disc Freewheel, SKU: 10020

Alloy Double Wall Board Track 11 Gauge SS 26 X 2.125 38mm Wide Rim Rear Disc Freewheel, SKU: 10105

Alloy Double Wall 12G Black SS 26 X 2.125 38mm Wide Rim Rear Disc Freewheel Assembled in U.S.A. SKU: 10135

Please call with questions Lynn 414-732-0017

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.