High reputation for 20191-T Swaged Hose Fiting for Brasilia Manufacturer

High reputation for 20191-T Swaged Hose Fiting for Brasilia Manufacturer Detail:

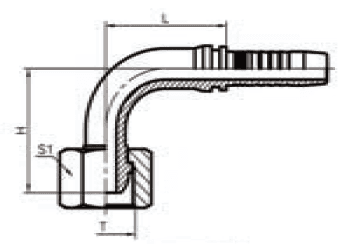

90°METRIC FEMALE MULTISEAL

|

PART NUMBER |

HOSE

|

S1 mm |

L mm |

H |

||

|

|

DN |

THREAD T |

DASH |

|

|

|

| S20191-12-04 | 6 | M12×1.5 | 17 | 19.5 | 32 | |

| S20191-14-04T | 6 | M14×1.5 | 17 | 19.5 | 35.5 | |

| S20191-14-05 | 8 | M14×1.5 | 19 | 19.5 | 40.5 | |

| S20191-16-04T | 6 | M16×1.5 | 19 | 20 | 34.5 | |

| S20191-16-05T | 8 | M16×1.5 | 19 | 20 | 41 | |

| S20191-18-06T | 10 | M18×1.5 | 22 | 20.5 | 44.5 | |

| S20191-18-08 | 13 | M18×1.5 | 24 | 22 | 50 | |

| S20191-22-08T | 13 | M22×1.5 | 27 | 22.8 | 52 | |

| S20191-24-10 | 16 | M24×1.5 | 30 | 25.5 | 56.5 | |

| S20191-27-10T | 16 | M27×1.5 | 32 | 23.5 | 54 | |

| S20191-30-12T | 19 | M30×2 | 36 | 24.5 | 67 | |

| S20191-39-16T | 25 | M39×2 | 46 | 29.5 | 72 | |

| S20191-45-20T | 32 | M45×2 | 55 | 31.5 | 85 | |

| S20191-52-24T | 38 | M52×2 | 60 | 33 | 100 | |

Product detail pictures:

Related Product Guide:

How to Replace a Hydraulic Hose Fitting

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

Bear Customer initially, High-quality first in mind, we work closely with our prospects and supply them with efficient and specialist companies for High reputation for 20191-T Swaged Hose Fiting for Brasilia Manufacturer, The product will supply to all over the world, such as: Sheffield, Paris, Nigeria, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

Homemade tester. Being far away from any sophisticated hydraulic valve testers, we have to solve the problems ourselves.

The hydraulic proportional valve (Rexroth 4WREE 6…and MOOG D633) which operated the cut-off on our pipemill is giving a problem minimum 1 time a year. The valve is operating in a dirty and harsh environment with splashing water, metal particles, etc.

There are many detailed specifications to be checked on a valve and this can be done only with a professional valve tester.

Important for us was to have a possibility to balance the delivery of each port.

Because we don’t use it every day, I wanted to have it small and moveable.

Locally they fabricated a hydraulic unit of 20 Bar.

The valve manifold is basically the same as used on the machine but a bit modified for this purpose. The electric/electronics for e.g. overheating protection for the motor, valve control, timer functions, etc are also DIY.

The first step was (when it was operational) to use a new valve to determine the relation of the quantity knob position and the quantity of oil, which are now displayed on a graph in order to compare it later with old valves.

The hydraulic experts among the viewers will immediately see that the chart used with this tester is not consistent with the 20 bar test chart from Bosch-Rexroth. This is because the characteristics and purpose of this tester is different.

This tester can not collect true data from a valve, but is designed as cheap and simple as possible to compare only. This has proven to be enough, for solving our problems.

By testing, a cycle of 10 sec opened port A and 10 sec port B.

The quantity oil collected in the bottles should be (in our case) the same.

It all looks primitive but during the last 4 years we haven’t put any new valve.

For owners of an old OTO pipemill type using hydraulic proportional valves for the cutt-off, please, see also the (homemade)”handheld proportional valve tester” in my youtube channel. With this handheld-tester you can test the cut-off function without removing the valve from the machine. All mill electrical connections will be disabled. The tester has a proportional valve control system, (hook-up)cutt-off sensors bracket and powered the pilot-valve. So, a quick diagnose system to determine if the problem is hydraulic or electrical.

In short: We use the handhold tester for a quick diagnose on the machine and the test-stand for separately checking and adjusting the valve.

An alternative way to test and adjust Hydraulic Proportional Valves is with a cheap and easy to build tester using Argon flow gauges and a little air pressure.

See in this channel “Simple Hydraulic Proportional Valve Tester (using 1 bar air pressure)” So, no need for an expensive hydraulic pump unit.

ronoverbeek@gmail.com

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.