factory wholesale good quality 20191-T Swaged Hose Fiting for Peru Factory

factory wholesale good quality 20191-T Swaged Hose Fiting for Peru Factory Detail:

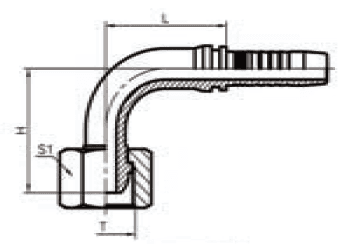

90°METRIC FEMALE MULTISEAL

|

PART NUMBER |

HOSE

|

S1 mm |

L mm |

H |

||

|

|

DN |

THREAD T |

DASH |

|

|

|

| S20191-12-04 | 6 | M12×1.5 | 17 | 19.5 | 32 | |

| S20191-14-04T | 6 | M14×1.5 | 17 | 19.5 | 35.5 | |

| S20191-14-05 | 8 | M14×1.5 | 19 | 19.5 | 40.5 | |

| S20191-16-04T | 6 | M16×1.5 | 19 | 20 | 34.5 | |

| S20191-16-05T | 8 | M16×1.5 | 19 | 20 | 41 | |

| S20191-18-06T | 10 | M18×1.5 | 22 | 20.5 | 44.5 | |

| S20191-18-08 | 13 | M18×1.5 | 24 | 22 | 50 | |

| S20191-22-08T | 13 | M22×1.5 | 27 | 22.8 | 52 | |

| S20191-24-10 | 16 | M24×1.5 | 30 | 25.5 | 56.5 | |

| S20191-27-10T | 16 | M27×1.5 | 32 | 23.5 | 54 | |

| S20191-30-12T | 19 | M30×2 | 36 | 24.5 | 67 | |

| S20191-39-16T | 25 | M39×2 | 46 | 29.5 | 72 | |

| S20191-45-20T | 32 | M45×2 | 55 | 31.5 | 85 | |

| S20191-52-24T | 38 | M52×2 | 60 | 33 | 100 | |

Product detail pictures:

Related Product Guide:

How to Replace a Hydraulic Hose Fitting

Importance of PVC Fittings

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for factory wholesale good quality 20191-T Swaged Hose Fiting for Peru Factory, The product will supply to all over the world, such as: Austria, New Delhi, Zurich, With the growing of the company, now our products sold and served at more than 15 countries around the world,such as Europe,North America,Middle-east,South America,Southern Asia and so on. As we bear in our mind that innovation is essential to our growth, new product development is constantly.Besides, Our flexible and efficient operation strategies,High quality products and competitive prices are exactly what our customers are looking for. Also a considerable service brings us good credit reputation.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!