Factory wholesale BC-W Metric Thread Bite Type Tube Fitting to Jakarta Importers

Factory wholesale BC-W Metric Thread Bite Type Tube Fitting to Jakarta Importers Detail:

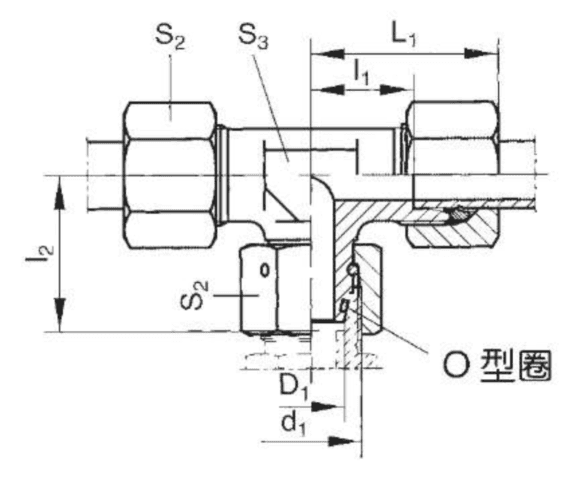

BRANCH TEE FITTINGS WITH SWIVEL NUT

|

PART NOMBER

|

MPa

|

TUBE O D.

|

d1 |

L1 |

l1 |

l2 |

S2 |

S3 |

O型圈 |

bar

|

| BC-06L | L | 06 | M12x1.5 | 27 | 12.0 | 26.0 | 14 | 12 | OR4.5×1.5 | 315 |

| BC-08L | 08 | M14x1.55 | 29 | 14.0 | 27.5 | 17 | 12 | OR6.5×1.5 | 315 | |

| BC-10L | 10 | M16x1.55 | 30 | 15.0 | 29.0 | 19 | 14 | OR8x1.5 | 315 | |

| BC-12L | 12 | M18x1.5 | 32 | 17.0 | 29.5 | 22 | 17 | OR10x1.5 | 315 | |

| BC-15L | 15 | M22x1.5 | 36 | 21.0 | 32.5 | 27 | 19 | OR12x2 | 315 | |

| BC-18L | 18 | M26x1.5 | 40 | 23.5 | 35.5 | 32 | 24 | OR15x2 | 315 | |

| BC-22L | 22 | M 30×2 | 44 | 27.5 | 38.5 | 36 | 27 | OR20x2 | 160 | |

| BC-28L | 28 | M 36×2 | 47 | 30.5 | 41.5 | 41 | 36 | OR26x2 | 160 | |

| BC-35L | 35 | M 45×2 | 56 | 34.5 | 51.0 | 50 | 41 | OR32x2.5 | 160 | |

| BC-42L | 42 | M 52×2 | 63 | 40.0 | 56.0 | 60 | 50 | OR38x2.5 | 160 | |

| BC-06S | S | 06 | M14x1.5 | 31 | 16.0 | 27.0 | 17 | 12 | OR4.5×1.5 | 630 |

| BC-08S | 08 | M16x1.5 | 32 | 17.0 | 27.5 | 19 | 14 | OR6.5×1.5 | 630 | |

| BC-10S | 10 | M18x1.5 | 34 | 17.5 | 30.0 | 22 | 17 | OR8x1.5 | 630 | |

| BC-12S | 12 | M20x1.5 | 38 | 21.5 | 31.0 | 24 | 17 | OR10x1.5 | 630 | |

| BC-14S | 14 | M22x1.5 | 40 | 22.0 | 35.0 | 27 | 19 | OR11x2 | 630 | |

| BC-16S | 16 | M24x1.5 | 43 | 24.5 | 36.5 | 30 | 24 | OR13x2 | 400 | |

| BC-20S | 20 | M 30×2 | 48 | 26.5 | 44.5 | 36 | 27 | OR16.3×2.4 | 400 | |

| BC-25S | 25 | M 36×2 | 54 | 30.0 | 50.0 | 46 | 36 | OR20.3×2.4 | 400 | |

| BC-30S | 30 | M 42×2 | 62 | 35.5 | 55.0 | 50 | 41 | OR25.3×2.4 | 400 | |

| BC-38S | 38 | M 52×2 | 72 | 41.0 | 63.0 | 60 | 50 | OR33.3×2.4 | 315 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

How to Replace a Hydraulic Hose Fitting

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Factory wholesale BC-W Metric Thread Bite Type Tube Fitting to Jakarta Importers, The product will supply to all over the world, such as: Lisbon, Georgia, Holland, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This 10 Tonne bench mounted hydraulic press is capable of bending, pressing or extruding and makes light work of installing ball joints, U-joints and pulleys. Ideal for many garage and workshop applications.

Includes a set of four steel mandrels, adaptor, fixing bracket and press plate, allowing this press to be used for a wider range of applications involving different sized work pieces.

Supplied with a detachable hydraulic hand pump and gauge. The pump can be removed and used for other purposes when not in use.

This press exceeds the latest UK safety standards and is CE, TUV and GS marked.

Billy Bobs Golf Training Video, Part 7 of 15 – Collared Ferrule Line

www.billybobsgolf.com

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.