Factory source manufacturing 22641-XX-XX Swaged Hose Fiting for Serbia Manufacturers

Factory source manufacturing 22641-XX-XX Swaged Hose Fiting for Serbia Manufacturers Detail:

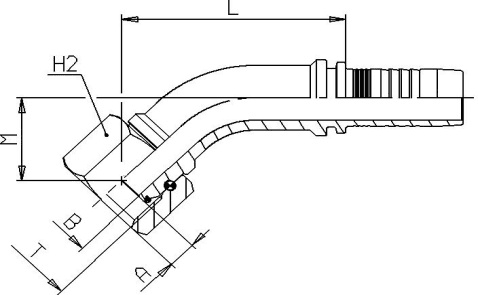

45° BSP O’RING FEMALE 60° CONE

|

PART NUMBER |

HOSE

|

THREAD T |

B mm |

L mm |

A mm |

M mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S226C1 – 04 – 04OR | 6 | 1/4″ | 04 | 1/4″ – 19 | 4 | 35,2 | 5,2 | 14,7 | 19 |

| S226C1 – 06 – 06OR | 10 | 3/8″ | 06 | 3/8″ – 19 | 7 | 40,9 | 6 | 17,3 | 22 |

| S226C1 – 08 – 08OR | 12 | 1/2″ | 08 | 1/2″ – 14 | 9,3 | 47,6 | 6,5 | 19,9 | 27 |

| S226C2 – 10 – 10OR | 16 | 5/8″ | 10 | 5/8″ – 14 | 12 | 56,8 | 9,7 | 25,8 | 30 |

| S226C2 – 12 – 12OR | 20 | 3/4″ | 12 | 3/4″ – 14 | 15 | 67,8 | 9 | 30,3 | 32 |

| S226C2 – 16 – 16OR | 25 | 1″ | 16 | 1″ – 11 | 19,5 | 84,4 | 10,5 | 37,4 | 38 |

| S226C2 – 16 – 20OR | 25 | 1″ | 16 | 1.1/4″ – 11 | 26 | 90,1 | 10,1 | 41,6 | 50 |

| S226C2 – 20 – 20OR | 32 | 1.1/4″ | 20 | 1.1/4″ – 11 | 26 | 100,7 | 10,1 | 44,8 | 50 |

| S226C2 – 20 – 24OR | 32 | 1.1/4″ | 20 | 1.1/2″ – 11 | 32 | 101,3 | 12,5 | 45,5 | 55 |

| S226C2 – 24 – 24OR | 40 | 1.1/2″ | 24 | 1.1/2″ – 11 | 32 | 112,5 | 12,5 | 49 | 55 |

| S226C2 – 24 – 32OR | 40 | 1.1/2″ | 24 | 2″ – 11 | 42 | 116 | 16,1 | 52,5 | 70 |

| S226C2 – 32 – 32OR | 50 | 2″ | 32 | 2″ – 11 | 42 | 132,9 | 16,1 | 55,7 | 70 |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Things to Know About Pipe Fitting Works

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for Factory source manufacturing 22641-XX-XX Swaged Hose Fiting for Serbia Manufacturers, The product will supply to all over the world, such as: Wellington, Swedish, Peru, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

Read more from Paul Heney on Hydraulics at https://www.mobilehydraulictips.com/blog/

Accumulators are pressure vessels that store hydraulic energy and deliver that energy back to the system on demand. This is analogous to the way a car battery stores energy. In hydro-pneumatic accumulators, compressible gas (nitrogen) is used to keep stored fluid pressurized. Hydro-pneumatic accumulators are used extensively in the global fluid power industry. In process plant operations, accumulators have multiple uses: pulsation dampeners, emergency power source, thermal expansion, transfer barrier for fluid separation, as prefill for large volume press applications, noise attenuation, leakage compensators, dispensers for pressurized lubricants, auxiliary power, and others.

There are different designs to separate gas from fluid. Bladder accumulators use a flexible closed bladder. Diaphragm accumulators use a flexible open diaphragm (membrane). Piston accumulators use a moveable piston with a system of seals. Float accumulators allow a buoyant valve to open and close the accumulator when necessary. For seamless high pressure bladder accumulators, chrome-moly steel has been used extensively for more than 40 years. This material has a high tensile strength, equivalent to AISI 4130. This material lends itself well to forming and machining and has a burst pressure more than 350% of design, that being 3.5:1 safety factor conforming to the ASME Code, Section VIII, Div. I. for unfired pressure vessels. Various applied coatings can enhance resistance to rust, corrosion, and abrasion. Most notably is the internal coating of phenolic resins. This material is an excellent choice to resist many common process fluids and has shown excellent chemical resistance. It is easily applied, and for bladder accumulators, aids in applications where lubrication from the working fluid is poor. Because of the smooth surface, it helps prevent the bladder from adhering to the internal wall surface during operation. Electro-less nickel plating is also very popular. This coating is applied approximately 2-mm thick internally and externally. Electro-less nickel has proven to be a very durable material, cost effective, and has been shown to be a viable alternative in many applications to the significantly more costly stainless steels, while maintaining the strength integrity of the carbon steel. This variation, as with the phenolic coated variation, can be combined with 316 stainless steel connections. These connections include the fluid and gas ends of the accumulator, along with the all of the internal component parts. An added feature of nickel plating also protects the accumulator on the outside, for those applications where water wash down or corrosive vapors may come into play. Electrolytic action between the stainless steel and electro-less nickel is seldom seen. There are several accumulator manufacturers that will produce accumulator housings using 316 stainless steel. However, because 316 stainless steel does not have the tensile strength of high carbon steels, the wall thickness must be adjusted to a thicker dimension to equal the strength of chrome-moly steel, especially for accumulator designs over 500 psi maximum allowable working pressure. Stainless steel housing hydraulic accumulators are usually special order, both in the piston and bladder configurations and therefore may have extended delivery times.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.