Factory selling Ferrule for R12 for azerbaijan Manufacturers

Factory selling Ferrule for R12 for azerbaijan Manufacturers Detail:

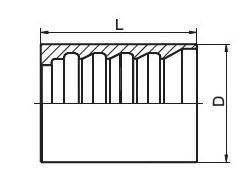

FERRULE FOR SAE 4SH .R12/32

| PART NUMBER | HOSE | Dmm | Lmm | ||

| DN | In | SIZE | |||

| S00401- 12 | 20 | 3/4″ | 12 | 35,5 | 50 |

| S00401 - 16 | 25 | 1″ | 16 | 46 | 60 |

| S00401 - 20 | 32 | 1.1/4″ | 20 | 52 | 66 |

| S00401 - 24 | 40 | 1.1/2″ | 24 | 62 | 75 |

| S00401 - 32 | 50 | 2″ | 32 | 77 | 79 |

Product detail pictures:

Related Product Guide:

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

Things to Know About Pipe Fitting Works

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for Factory selling Ferrule for R12 for azerbaijan Manufacturers, The product will supply to all over the world, such as: Indonesia, Sheffield, Miami, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

1997-2000 Kia Sportage Fuel Tank Filler Hose Joint 4 Door Only Genuine New

Only fits the 4 Door Sportage Model built between 09/01/96 and 10/01/00

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.