factory low price P20491 one piece type for Cyprus Manufacturer

factory low price P20491 one piece type for Cyprus Manufacturer Detail:

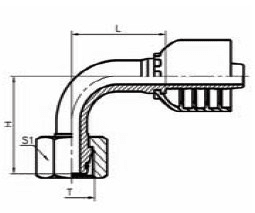

90° O’RING METRIC FEMALE 24° CONE LIGHT TYPE

|

PART NUMBER |

HOSE

|

THREAD T |

PIPE |

B mm |

L mm |

A mm |

M mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

|

| P204B1 – 03 – 12 | 5 | 3/16″ | 03 | M12x1,5 | 6 | 3 | 25.5 | 1,2 | 30,6 | 14 |

| P204B1 – 04 – 14 | 6 | 1/4″ | 04 | M14x1,5 | 8 | 4 | 29 | 1,8 | 31 | 17 |

| P204B1 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 10 | 5,5 | 29 | 2,3 | 31 | 19 |

| P204B1 – 05 – 16 | 8 | 5/16″ | 05 | M16x1,5 | 10 | 5,5 | 31 | 2,3 | 32,7 | 19 |

| P204B1 – 05 – 18 | 8 | 5/16″ | 05 | M18x1,5 | 12 | 7 | 31 | 2,5 | 33,5 | 22 |

| P204B1 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 12 | 7 | 34 | 2,5 | 36,7 | 22 |

| P204B1 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 15 | 9,5 | 34 | 2,5 | 39,9 | 27 |

| P204B1 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 15 | 9,3 | 40 | 2,5 | 43,8 | 27 |

| P204B1 – 08 – 26 | 12 | 1/2″ | 08 | M26x1,5 | 18 | 12 | 40 | 2,5 | 46,3 | 32 |

| P204B1 – 10 – 26 | 16 | 5/8″ | 10 | M26x1,5 | 18 | 12 | 40 | 2,5 | 54,3 | 32 |

| P204B1 – 12 – 30 | 20 | 3/4″ | 12 | M30x2 | 22 | 15 | 55 | 3,5 | 61,9 | 36 |

| P204B1 – 12 – 36 | 20 | 3/4″ | 12 | M36x2 | 28 | 19,5 | 55 | 3,7 | 65,1 | 41 |

| P204B1 – 16 – 36 | 25 | 1″ | 16 | M36x2 | 28 | 19,5 | 73 | 3,7 | 72 | 41 |

| P204B1 – 20 – 45 | 32 | 1.1/4″ | 20 | M45x2 | 35 | 26 | 87,8 | 4 | 87,4 | 50 |

| P204B1 – 24 – 52 | 40 | 1.1/2″ | 24 | M52x2 | 42 | 32 | 103 | 4,5 | 101,5 | 60 |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

We stick to our enterprise spirit of Quality, Efficiency, Innovation and Integrity. We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for factory low price P20491 one piece type for Cyprus Manufacturer, The product will supply to all over the world, such as: Cyprus, New York, Iran, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

What is CENTER PIVOT IRRIGATION? What does CENTER PIVOT IRRIGATION mean? CENTER PIVOT IRRIGATION meaning – CENTER PIVOT IRRIGATION definition – CENTER PIVOT IRRIGATION explanation.

Source: Wikipedia.org article, adapted under https://creativecommons.org/licenses/by-sa/3.0/ license.

SUBSCRIBE to our Google Earth flights channel – https://www.youtube.com/channel/UC6UuCPh7GrXznZi0Hz2YQnQ

Center-pivot irrigation (sometimes called central pivot irrigation), also called waterwheel and circle irrigation, is a method of crop irrigation in which equipment rotates around a pivot and crops are watered with sprinklers. A circular area centered on the pivot is irrigated, often creating a circular pattern in crops when viewed from above (sometimes referred to as crop circles). Most center pivots were initially water-powered, and today most are propelled by electric motors.

Center pivot irrigation is a form of overhead sprinkler irrigation consisting of several segments of pipe (usually galvanized steel or aluminum) joined together and supported by trusses, mounted on wheeled towers with sprinklers positioned along its length. The machine moves in a circular pattern and is fed with water from the pivot point at the center of the circle. The outside set of wheels sets the master pace for the rotation (typically once every three days). The inner sets of wheels are mounted at hubs between two segments and use angle sensors to detect when the bend at the joint exceeds a certain threshold, and thus, the wheels should be rotated to keep the segments aligned. Center pivots are typically less than 1600 feet (500 meters) in length (circle radius) with the most common size being the standard 1/4 mile (400 m) machine.

To achieve uniform application, center pivots require an even emitter flow rate across the radius of the machine. Since the outer-most spans (or towers) travel farther in a given time period than the innermost spans, nozzle sizes are smallest at the inner spans and increase with distance from the pivot point. Aerial views show fields of circles created by the watery tracings of “quarter- or half-mile of the center-pivot irrigation pipe,” created by center pivot irrigators which use “hundreds and sometimes thousands of gallons a minute.”

Most center pivot systems now have drops hanging from a u-shaped pipe called a gooseneck attached at the top of the pipe with sprinkler heads that are positioned a few feet (at most) above the crop, thus limiting evaporative losses and wind drift. There are many different nozzle configurations available including static plate, moving plate and part circle. Pressure regulators are typically installed upstream of each nozzle to ensure each is operating at the correct design pressure.

Drops can also be used with drag hoses or bubblers that deposit the water directly on the ground between crops. This type of system is known as LEPA (Low Energy Precision Application) and is often associated with the construction of small dams along the furrow length (termed furrow diking/dyking). Crops may be planted in straight rows or are sometimes planted in circles to conform to the travel of the irrigation system.

Originally, most center pivots were water-powered. These were replaced by hydraulic systems and electric motor-driven systems. Most systems today are driven by an electric motor mounted at each tower.

For a center pivot to be used, the terrain needs to be reasonably flat; but one major advantage of center pivots over alternative systems is the ability to function in undulating country. This advantage has resulted in increased irrigated acreage and water use in some areas. The system is in use, for example, in parts of the United States, Australia, New Zealand, Brazil and also in desert areas such as the Sahara and the Middle East.

The center-pivot irrigation system is considered to be a highly efficient system which helps conserve water.

Center pivot irrigation typically uses less water compared to many surface irrigation and furrow irrigation techniques, which reduces the expenditure of and conserves water. It also helps to reduce labor costs compared to some ground irrigation techniques, which are often more labor-intensive. Some ground irrigation techniques involve the digging of channels on the land for the water to flow, whereas the use of center-pivot irrigation can reduce the amount of soil tillage that occurs and helps to reduce water runoff and soil erosion that can occur with ground irrigation. Less tillage encourages more organic materials and crop residue to decompose back into the soil, and reduces soil compaction….

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.