Factory directly provide 87643-Interlock Hose Fitting for Congo Factory

Factory directly provide 87643-Interlock Hose Fitting for Congo Factory Detail:

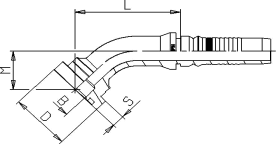

45° SAE FLANGE 6000 P.S.I.

|

PART NUMBER |

HOSE

|

FLANGE

|

B mm |

L mm |

D mm |

M

mm |

S

mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| H876C0 – 10 – 12 | 16 | 5/8″ | 10 | 3/4″ | 18 | 61,9 | 41,3 | 28 | 8,76 |

| H876C0 – 12 – 12 | 20 | 3/4″ | 12 | 3/4″ | 18 | 69,9 | 41,3 | 30,5 | 8,76 |

| H876C0 – 12 – 16 | 20 | 3/4″ | 12 | 1″ | 23 | 72,6 | 47,6 | 33,3 | 9,53 |

| H876C0 – 16 – 16 | 25 | 1″ | 16 | 1″ | 23 | 85,5 | 47,6 | 37,5 | 9,53 |

| H876C0 – 16 – 20 | 25 | 1″ | 16 | 1.1/4″ | 30 | 87,9 | 54 | 40,1 | 10,29 |

| H876C0 – 20 – 20 | 32 | 1.1/4″ | 20 | 1.1/4″ | 30 | 100,2 | 54 | 43 | 10,29 |

| H876C0 – 20 – 24 | 32 | 1.1/4″ | 20 | 1.1/2″ | 36 | 105,1 | 63,5 | 47,9 | 12,57 |

| H876C0 – 24 – 24 | 40 | 1.1/2″ | 24 | 1.1/2″ | 36 | 113 | 63,5 | 51,8 | 12,57 |

| H876C0 – 24 – 32 | 40 | 1.1/2″ | 24 | 2″ | 48 | 120,4 | 79,4 | 59,2 | 12,57 |

| H876C0 – 32 – 32 | 50 | 2″ | 32 | 2″ | 48 | 150,8 | 79,4 | 67,8 | 12,57 |

Product detail pictures:

Related Product Guide:

How to Replace a Hydraulic Hose Fitting

Importance of PVC Fittings

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for Factory directly provide 87643-Interlock Hose Fitting for Congo Factory, The product will supply to all over the world, such as: Cancun, Durban, Manila, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

High speed corrugated siphon pipe making machine for sanitary application, available in blow forming& vacuum forming.

Manufacturer: Qingdao Extrusion Technology Co.,Ltd.

www.extruder.com.cn

Email: info@extruder.com.cn

Whatsapp: 008613789849211

Dishwasher hose making machine, kitchen water hose pipe machine, basin sink pipe hose making machine

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.