2017 High quality DIN EN853 1SN-2SN for Madagascar Manufacturers

2017 High quality DIN EN853 1SN-2SN for Madagascar Manufacturers Detail:

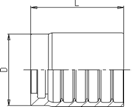

FERRULE FOR SAE 100R1AT – R2AT / DIN EN 853 1SN – 2SN / SAE 100R16 SAE 100R17

|

PART NUMBER |

HOSE

|

D mm |

L mm |

||

|

|

DN |

In |

SIZE |

|

|

| S05000 – 03 | 5 | 3/16″ | 03 | 20 | 23,5 |

| S05000 – 04 | 6 | 1/4″ | 04 | 23 | 30 |

| S05000 – 05 | 8 | 5/16″ | 05 | 24 | 30 |

| S05000 – 06 | 10 | 3/8″ | 06 | 26 | 32 |

| S05000 – 08 | 12 | 1/2″ | 08 | 29 | 34 |

| S05000 – 10 | 16 | 5/8″ | 10 | 33 | 37 |

| S05000 – 12 | 20 | 3/4″ | 12 | 37 | 42 |

| S05000 – 16 | 25 | 1″ | 16 | 46 | 51 |

| S05000 – 20 | 32 | 1.1/4″ | 20 | 59 | 59 |

| S05000 – 24 | 40 | 1.1/2″ | 24 | 67 | 67 |

| S05000 – 32 | 50 | 2″ | 32 | 80 | 72 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

Tube Fittings and Pipe Fittings – Double Ferrule Tube Fittings

Sticking towards the theory of Super Good quality, Satisfactory service ,We are striving to become a superb business enterprise partner of you for 2017 High quality DIN EN853 1SN-2SN for Madagascar Manufacturers, The product will supply to all over the world, such as: azerbaijan, Thailand, Holland, We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of Standing in Domestic Markets, Walking into International Markets. We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Traditional work on the larger wooden vessels has always been labour intensive and hard graft. The scantling sizes of all the timbers have to increase which means everything is larger and generally heavier. The skills learnt on small and large vessels are generally interchangeable, but on some tasks more force is required.

This is demonstrated very well in the fitting of the first plank to the Grayhound; with a plank thickness of 2″ (51mm) and well over half the length of her, it is not going to be easy. The garboard is the plank (strake) next to the keel and rebated into the keel, stem and the stern post. Planking up a carvel vessel can occur in any order; they don’t have to be sequential. Starting planking is an important moment in the life of a project, with the

garboard one of the more difficult planks to get right.

The process is demonstrated in the accompanying video clips with a step-by-step guide.

The process was captured on film by observing the garboard plank being fitted on the

Grayhound. There is no discussion with the shipwright during the process, but all the key

tasks are recorded in the subtitles.

Before the garboard could be fitted the following steps must have occurred:

· The rebate is cut into the keel, stem and stern post,

· All the frames are faired, usually only for the current plank

· A plank template is taken

· Planking stock is selected and using the template the plank is cut out

· The plank is prepared for fitting

Part 1

· The rebate pocket, frames, deadwoods, stem etc. are covered in tar.

· The plank is offered up

· The plank is clamped in position where it is flattest (usually at the midships)

· Clamping worked forward or aft depending on the plank position.

· The twist in the plank increases as you move forward, usually this is aided by the

use of steam. Steam makes the plank very supple and enables it to be forced into

the shape required for the plank. However, it is a slow process and makes the plank

very wet, so it would be fitted twice typically – once during the steaming process and

then secondly once the plank is cooled.

For the Grayhound they intended not to use steam in order to speed up the process

and it turns out it was not necessary for any of the planks fitted. So they were going

to be fitted dry and cold.

· Once clamped, check the plank is sitting in the rebate pocket and is up against the

frames.

· The planks will be fixed with screws and treenails:

o Plan the location of the fixings, mark the wood if necessary

o Drill a hole for the head of the screw

o Drill a hole for the shank of the screw in the plank

o Drill a pilot hole through the plank into the centreline timbers

o Use tape on the drill to maintain the correct depths

o Dip the screws in grease to help lubricate them

o Using a flat screw bit, screw the fixings in

o Drill a larger hole for the treenails, cover in glue and wedge the internal end

before hammering the treenail in.

o Once in, wedge the outer end of the treenail (this expands the end of the

treenail stopping it coming out).

o Treenails need to be well seasoned before use, this enables them to expand

when taking up moisture..

o Screw holes are plugged with wooden dowels.

· Once all the glue has gone off, these loose ends can be cut back using a Fein

Multimaster type hand saw.

Once the garboard has been fitted, the other garboard would usually be fitted next and the planking will carry on in pairs until completed.

It was an aim to demonstrate steaming large vessel planks into position, either on the

vessel in the bag technique or using a large steam box. Sadly this skill was not happening during the life of the project.

tube bender pipe bending machine mandrel conduit tubing bend tool

Email: wawadeni3915@gmail.com

Contact: Frank

Mobile phone number/Whatsapp: 008617769915630

Skype: zeng39152013

QQ/Wechat: 282473796

Manufacturer: Zhejiang Luosbg Machine Co.,Ltd

If you want to get the detailed quotation of this machine, please contact me via above details.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!