2017 High quality 2D9-W Metric Thread Bite Type Tube Fitting Wholesale to Canada

2017 High quality 2D9-W Metric Thread Bite Type Tube Fitting Wholesale to Canada Detail:

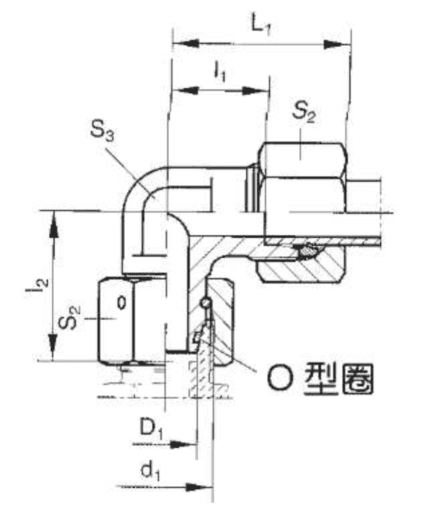

90º ELBOW REDUCER TUBE ADAPTOR WITH SWIVEL NUT

|

PART NOMBER

|

MPa

|

TUBE O D.

|

d1 |

L1 |

l1 |

l2 |

S2 |

S3 |

O型圈 |

bar

|

| 2C9-06L |

L |

06 |

M12x1.5 |

27 |

12.0 |

26.0 |

14 |

12 |

OR4.5×1.5 |

315 |

| 2C9-08L |

|

08 |

M14x1.55 |

29 |

14.0 |

27.5 |

17 |

12 |

OR6.5×1.5 |

315 |

| 2C9-10L |

|

10 |

M16x1.55 |

30 |

15.0 |

29.0 |

19 |

14 |

OR8x1.5 |

315 |

| 2C9-12L |

|

12 |

M18x1.5 |

32 |

17.0 |

29.5 |

22 |

17 |

OR10x1.5 |

315 |

| 2C9-15L |

|

15 |

M22x1.5 |

36 |

21.0 |

32.5 |

27 |

19 |

OR12x2 |

315 |

| 2C9-18L |

|

18 |

M26x1.5 |

40 |

23.5 |

35.5 |

32 |

24 |

OR15x2 |

315 |

| 2C9-22L |

|

22 |

M 30×2 |

44 |

27.5 |

38.5 |

36 |

27 |

OR20x2 |

160 |

| 2C9-28L |

|

28 |

M 36×2 |

47 |

30.5 |

41.5 |

41 |

36 |

OR26x2 |

160 |

| 2C9-35L |

|

35 |

M 45×2 |

56 |

34.5 |

51.0 |

50 |

41 |

OR32x2.5 |

160 |

| 2C9-42L |

|

42 |

M 52×2 |

63 |

40.0 |

56.0 |

60 |

50 |

OR38x2.5 |

160 |

| 2C9-06S |

S |

06 |

M14x1.5 |

31 |

16.0 |

27.0 |

17 |

12 |

OR4.5×1.5 |

630 |

| 2C9-08S |

|

08 |

M16x1.5 |

32 |

17.0 |

27.5 |

19 |

14 |

OR6.5×1.5 |

630 |

| 2C9-10S |

|

10 |

M18x1.5 |

34 |

17.5 |

30.0 |

22 |

17 |

OR8x1.5 |

630 |

| 2C9-12S |

|

12 |

M20x1.5 |

38 |

21.5 |

31.0 |

24 |

17 |

OR10x1.5 |

630 |

| 2C9-14S |

|

14 |

M22x1.5 |

40 |

22.0 |

35.0 |

27 |

19 |

OR11x2 |

630 |

| 2C9-16S |

|

16 |

M24x1.5 |

43 |

24.5 |

36.5 |

30 |

24 |

OR13x2 |

400 |

| 2C9-20S |

|

20 |

M 30×2 |

48 |

26.5 |

44.5 |

36 |

27 |

OR16.3×2.4 |

400 |

| 2C9-25S |

|

25 |

M 36×2 |

54 |

30.0 |

50.0 |

46 |

36 |

OR20.3×2.4 |

400 |

| 2C9-30S |

|

30 |

M 42×2 |

62 |

35.5 |

55.0 |

50 |

41 |

OR25.3×2.4 |

400 |

| 2C9-38S |

|

38 |

M 52×2 |

72 |

41.0 |

63.0 |

60 |

50 |

OR33.3×2.4 |

315 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

Importance of PVC Fittings

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for 2017 High quality 2D9-W Metric Thread Bite Type Tube Fitting Wholesale to Canada, The product will supply to all over the world, such as: Jersey, The Swiss, Detroit, If you are interested in any of our products and solutions or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

From https://www.kevincaron.com – Artist Kevin Caron shares how to fill a gap – and why you really shouldn’t ….

Caron first addresses why you should avoid gaps altogether. It’s always better to make sure your fit is right, with straight lines, smooth cuts and tight joints, getting your fit up and prep done first. He explains that a tight fit leads to a good weld structurally. That’s not as important, perhaps, with something like art, but if you are building buildings or bridges, for example, it has to be a good joint. The weld will be X-rayed and inspected for soundness, porosity, gaps, etc. The space in a gap lets air come up and cause porosity because you’re super-heating the air above and below the gap and have a puddle of molten metal that pulls the air up through the gap and into the weld. By not having a good, tight joint, you’re causing more problems for yourself. Caron says a good fit is just part of being a good welder.

Regardless, Caron shows you how to fill a gap. He sets up two pieces of 1/4″ plate with a V-gap, with one end fairly close and the other end wide. Again, he emphasizes that this is for aesthetic, not structural welding.

Using Longevity’s ProMTS 200 because he loves the MIG welder in it, Caron first gives the metal a few tacks so the steel won’t move. Next he’s ready to run a welding bead. He’s got the MIG welder set at 23 volts for weld tacking, so he’s going to turn it down a little to 21.5, but leave the wire feed as it is at 147. Caron reminds us that, with this machine, that doesn’t mean 147 inches a minute (he’s not sure how Longevity measures wire speed), but it’s about two-thirds of the way up.

Before Caron starts welding, though, he addresses whether you can just run your bead from one end to the other. He explains he wouldn’t. Because of the gap, he’s found that if you try to just run a bead from one end to the other, one piece of metal will move away as you are welding, so the gap actually widens. Caron says it’s best to tack it on one end, tack it on the other, then he likes to hopscotch back and forth. He’ll tack it in the middle, then run a short bead between two of the tacks, then go to another area and run a bead between two other tacks, etc., just filling it in as he works his way out. That helps spread out the heat more evenly and reduces warpage on thinner metals as well as prevents blow-outs. Caron then runs the bead.

He says that that voltage worked well as he filled in the sections between the tacks. He also wove back and forth to fill in larger areas, “stealing” a little metal from each side of the gap. Then Caron shows the first weld at 21.5 volts and another at 21.2. From the back you can see that both welds got good penetration all the way through.

A couple of other ways to fill gaps include straightening a coathanger and laying it inside the gap, getting a piece of thick copper -1/8″ or 1/4″ preferred – and using it as a backer because the steel won’t stick to the copper. You can clamp or prop the copper, which gives the molten steel something to run up against as you are welding. Depending upon your design, you could even back it with another piece of steel and just weld it in.

For more how-to videos, visit https://www.kevincaron.com

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.