2017 Good Quality 29611 Swaged Hose Fiting for Cannes Importers

2017 Good Quality 29611 Swaged Hose Fiting for Cannes Importers Detail:

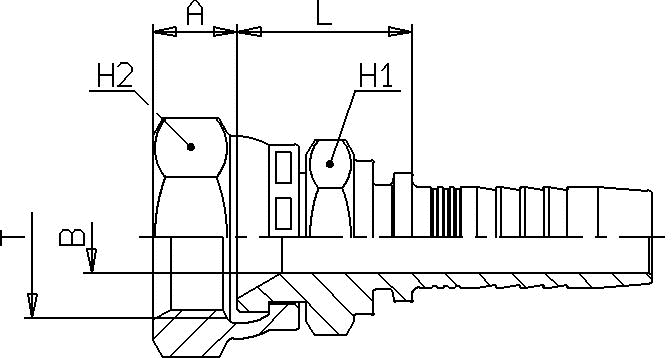

J.I.S. FEMALE 60° CONE SEAT TYPE F (CRIMPED – BACK NUT)

|

PART NUMBER |

HOSE

|

THREAD T |

B mm |

L mm |

A mm |

H1 mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S296A3 – 04 – 04D | 6 | 1/4″ | 04 | 1/4″ – 19 | 4 | 21 | 8,5 | 17 | 19 |

| S296A3 – 06 – 06D | 10 | 3/8″ | 06 | 3/8″ – 19 | 7 | 22,1 | 9 | 19 | 22 |

| S296A3 – 08 – 08D | 12 | 1/2″ | 08 | 1/2″ – 14 | 9,3 | 22,8 | 11 | 22 | 27 |

| S296A3 – 12 – 12D | 20 | 3/4″ | 12 | 3/4″ – 14 | 15 | 26 | 13,5 | 30 | 36 |

| S296A3 – 16 – 16D | 25 | 1″ | 16 | 1″ – 11 | 19,5 | 30,8 | 14 | 36 | 41 |

Product detail pictures:

Related Product Guide:

Things to Know About Pipe Fitting Works

How to Replace a Hydraulic Hose Fitting

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for 2017 Good Quality 29611 Swaged Hose Fiting for Cannes Importers, The product will supply to all over the world, such as: Sheffield, Costa Rica, Estonia, In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

Are you looking for the Robina Plumber Leaking Toilet and theRobina Plumber Tankless Water Heater

Vital Plumbing Services That a Experienced Plumbing Contractor Provide

Plumbing is the intricate system of assembly devices, drains, fittings, pipes, tubes and valves etc, that distribute water in a home for a variety of purposes in addition to remove waste water from utilities. Plumbing is certainly distinctive from sewage systems; simply this means that plumbing may be used to handle the water supply and drainage lines in a property whereas sewage systems include a small grouping of buildings.

The term’plumbing’arises from the Latin word’plumbum’which stands for “Lead”; pipes were once produced from lead and lead is denoted by the abbreviation’Pb ‘.

Plumbers and plumbing contractors are the true forces behind the many luxuries we experience in our homes – continuous flow of cold and warm water and clog-free sinks and drains. A minor plumbing problem or perhaps a faulty sink or tap can leave a home flooded very quickly; hence it is totally very important to enlist the services of established and licensed plumbing contractors to keep up homes and buildings.

An excellent plumbing contractor should have the experience, skills and qualification; furthermore the contractor should likewise have good management and financial skills to interact and negotiate with clients. An established and skilled plumbing contractor has to understand a house or even a family’s requirement for a streamlined plumbing system and there are lots of areas where they could extend their help and services.

This really is even more vital in the case of building or investing in a new home; several home builders enlist the services of a plumbing contractor to liaise with home buyers and suggest any changes or remedies before fittings and fixtures are installed.

The Importance Of Understand Neighborhood Landscaping

A great plumbing contractor needs to be well aware of the neighborhood landscaping to understand how the presence of old trees and tree roots may come in how of plumbing lines if a new home is being built; on another hand, if a home has old pipes of laid before the plumbing code standards were put set up, he has also to know how to replace the old pipes with new ones that’ll not compromise the existing landscape but remain firm and damage free at all times.

Appliances

A licensed and reputed plumbing contractor should likewise have the skills to inspect water lines and connections to home appliances like heaters, dish washers, washing machines etc., and be able to suggest ways and methods to maintain pipes, filters and drains without corrosion and damage.

Plumbing Vents

Some homeowners are not even conscious that pipelines and vents for home plumbing extend from the roof in which regular maintenance is important to help keep them free of becoming clogged with debris, tree leaves, twigs and other elements. A great plumbing contractor has to know the general layout of the building with knowledge about the positioning of plumbing vents; he should also be able to suggest practical and usable remodel if necessary.

Home Heating

A reputed plumbing contractor can perform an evaluation of the heating system and suggest any upgrades and replacements if necessary; this should not be limited to central heating in modern homes but and to furnace units and boilers in old homes.

Robina Plumber Bathtub Drain Repairs

Robina Plumber Commercial Plumbing, Robina Plumber 24 Hour Plumber, Robina Plumber Blocked Sewer, Robina Plumber Shower Repair, Robina Plumber Plumbing Pipe, Robina Plumber Sink Drain, Robina Plumber Plumbing Fittings, Robina Plumber Electric Hot Water Heater, Robina Plumber Plumbing Snake, Robina Plumber Clogged Toilet, Robina Plumber Blocked Sink, Robina Plumber Toilet Plumbing, Robina Plumber Replacing A Toilet, Robina Plumber Plumbing Companies, Robina Plumber Unclog Toilet, Robina Plumber Water Tank Installation, Robina Plumber Electric Water Heater Repairs, Robina Plumber Bathtub Drain Repairs, Robina Plumber Hot Water Plumbing, Robina Plumber Bathtub Repair, Robina Plumber Cheap Plumber, Robina Plumber Pipe Bursting, Robina Plumber Water Heater Price, Robina Plumber Rooter, Robina Plumber Shower Drain Repairs, Robina Plumber Plumbing Pipe Repairs, Robina Plumber Plumbing Maintenance, Robina Plumber Plumbing Quotes, Robina Plumber Plumber Cost, Robina Plumber Plumber Hourly Rate, Robina Plumber Define Plumb, Robina Plumber Toilet Repair, Robina Plumber Clogged Sink, Robina Plumber Unclog Drain, Robina Plumber Tankless Water Heater, Robina Plumber Water Tank Repair, Robina Plumber Bathroom Drain, Robina Plumber Plumbing Inspection, Robina Plumber Find A Plumber, Robina Plumber Bathroom Plumbing, Robina Plumber Leaking Pipe, Robina Plumber Clogged Shower Drain, Robina Plumber Affordable Plumbing, Robina Plumber Shower

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!