2017 China New Design P20411 one piece type to Singapore Factory

2017 China New Design P20411 one piece type to Singapore Factory Detail:

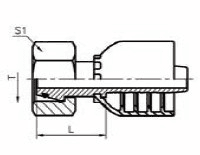

O’RING METRIC FEMALE 24° CONE LIGHT TYPE DIN 3865 (DKOL)

|

PART NUMBER |

HOSE

|

THREAD T |

PIPE |

B mm |

L mm |

A mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| P204A1 – 03 – 12 | 5 | 3/16″ | 03 | M12x1,5 | 6 | 3 | 24,1 | 1,2 | 14 |

| P204A1 – 04 – 14 | 6 | 1/4″ | 04 | M14x1,5 | 8 | 4 | 24,5 | 1,8 | 17 |

| P204A1 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 10 | 5,5 | 26 | 2,3 | 19 |

| P204A1 – 05 – 16 | 8 | 5/16″ | 05 | M16x1,5 | 10 | 5,5 | 26 | 2,3 | 19 |

| P204A1 – 05 – 18 | 8 | 5/16″ | 05 | M18x1,5 | 12 | 7 | 26 | 2,5 | 22 |

| P204A1 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 12 | 7 | 26,6 | 2,5 | 22 |

| P204A1 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 15 | 9,5 | 30,1 | 2,5 | 27 |

| P204A1 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 15 | 9,3 | 29,3 | 2,5 | 27 |

| P204A1 – 08 – 26 | 12 | 1/2″ | 08 | M26x1,5 | 18 | 12 | 31,3 | 2,5 | 32 |

| P204A1 – 10 – 26 | 16 | 5/8″ | 10 | M26x1,5 | 18 | 12 | 30,3 | 2,5 | 32 |

| P204A1 – 12 – 30 | 20 | 3/4″ | 12 | M30x2 | 22 | 15 | 33 | 3,5 | 36 |

| P204A1 – 12 – 36 | 20 | 3/4″ | 12 | M36x2 | 28 | 19,5 | 34,5 | 3,7 | 41 |

| P204A1 – 16 – 36 | 25 | 1″ | 16 | M36x2 | 28 | 19,5 | 34,3 | 3,7 | 41 |

| P204A1 – 20 – 45 | 32 | 1.1/4″ | 20 | M45x2 | 35 | 26 | 39 | 4 | 50 |

| P204A1 – 24 – 52 | 40 | 1.1/2″ | 24 | M52x2 | 42 | 32 | 39,5 | 4,5 | 60 |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

How to Replace a Hydraulic Hose Fitting

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for 2017 China New Design P20411 one piece type to Singapore Factory, The product will supply to all over the world, such as: Saudi Arabia, Zimbabwe, Gambia, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

شركة سباكة بالرياض

https://sites.google.com/site/alfahedclean/plumbing-company-in-riyadh شركة سباكة بالرياض

https://www.goodreads.com/topic/show/18338311

https://www.goodreads.com/topic/show/18338310

https://www.goodreads.com/topic/show/18338308

شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض شركة سباكة بالرياض

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.