2 Years’ Warranty for DIN EN853 1SN-2SN Export to Cairo

2 Years’ Warranty for DIN EN853 1SN-2SN Export to Cairo Detail:

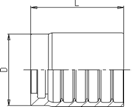

FERRULE FOR SAE 100R1AT – R2AT / DIN EN 853 1SN – 2SN / SAE 100R16 SAE 100R17

|

PART NUMBER |

HOSE

|

D mm |

L mm |

||

|

|

DN |

In |

SIZE |

|

|

| S05000 – 03 | 5 | 3/16″ | 03 | 20 | 23,5 |

| S05000 – 04 | 6 | 1/4″ | 04 | 23 | 30 |

| S05000 – 05 | 8 | 5/16″ | 05 | 24 | 30 |

| S05000 – 06 | 10 | 3/8″ | 06 | 26 | 32 |

| S05000 – 08 | 12 | 1/2″ | 08 | 29 | 34 |

| S05000 – 10 | 16 | 5/8″ | 10 | 33 | 37 |

| S05000 – 12 | 20 | 3/4″ | 12 | 37 | 42 |

| S05000 – 16 | 25 | 1″ | 16 | 46 | 51 |

| S05000 – 20 | 32 | 1.1/4″ | 20 | 59 | 59 |

| S05000 – 24 | 40 | 1.1/2″ | 24 | 67 | 67 |

| S05000 – 32 | 50 | 2″ | 32 | 80 | 72 |

Product detail pictures:

Related Product Guide:

Importance of PVC Fittings

Understanding Hydraulic Hose Fittings

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for 2 Years’ Warranty for DIN EN853 1SN-2SN Export to Cairo, The product will supply to all over the world, such as: Anguilla, Ethiopia, Uruguay, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

https://www.maneklal.com/English/SmallScale/BucketHandle.htm

Bucket / Paint Can Handle Making Machine to make East West Type (Bent Ends) Bucket Handles

Máquina para fabricar Asas de Metal para Cubos / Cubetas de Plástico / Asas tipo Este – Oeste o Extremos Doblados

machine for making steel handles for plastic buckets / pail / container / paint cans / vessel

Maneklal Global Exports

67 Bajaj Bhavan, Nariman Point, Mumbai – 400021, India

Tel: (+91 22) 22041340 / 41 / 42

Fax: (+91 22) 22041389

e-mail: sales@maneklalexports.com

web site: https://www.maneklal.com

The Channel Master Coaxial Connector Installation Kit includes 5 Channel Master F-Type compression connectors, the Channel Master compression tool and the Channel Master cable preparation tool (cable stripper). Designed for professionals and the Do-it-Yourself consumer, the kit provides everything needed to attach high quality Channel Master compression connectors at the end of a coaxial cable. Popular consumer applications for this kit include, making short indoor coax cables, long outdoor cables and replacing old low quality connectors installed during construction. The kit is also popular as a starter kit for new antenna installers, electricians, home theater installers and other professional coaxial cable installers. The included connectors can be used indoors, outdoors and are compatible with standard, tri and quad shield RG-6 coaxial cable.

For more information or to place an order for the Channel Master Coaxial Connector Installation Kit, please visit:

https://www.channelmaster.com/Coaxial_Connectors_Installation_Kit_p/cm-7170bdl.htm

Connect with us on Facebook:

https://www.facebook.com/mychannelmaster

Follow us on Twitter:

https://twitter.com/ChannelMaster

For more Informative product related videos from Channel Master, please go to:

https://www.youtube.com/playlist?list=PL32OVc2iZcstKM-SV0eOw7kr7M2YbKOqP

To see more videos from Channel Master, please subscribe to our Youtube channel:

https://www.youtube.com/user/channelmasterstore

We have been looking for a professional and responsible supplier, and now we find it.