18 Years Factory offer 10411 Swaged Hose Fiting to Sevilla Factory

18 Years Factory offer 10411 Swaged Hose Fiting to Sevilla Factory Detail:

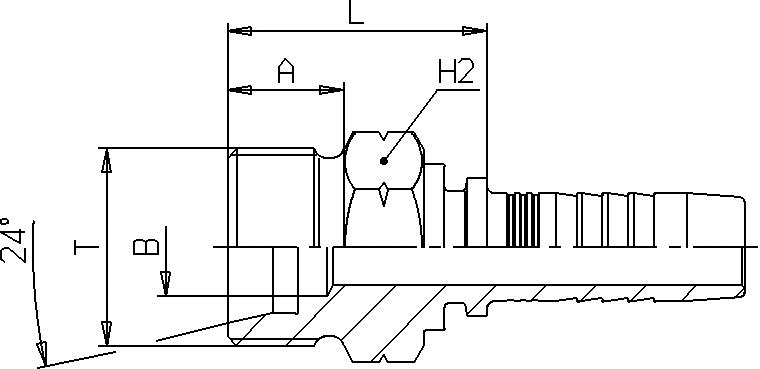

METRIC MALE 24° CONE SEAT LIGHT TYPE DIN 3861 ( CEL )

|

PART NUMBER |

HOSE

|

THREAD T

|

PIPE |

B mm |

L mm |

A mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

| S104A0 – 03 – 12 | 5 | 3/16″ | 03 | M12x1,5 | 6 | 3 | 21,1 | 10 | 14 |

| S104A0 – 04 – 12 | 6 | 1/4″ | 04 | M12x1,5 | 6 | 4 | 21,5 | 10 | 14 |

| S104A0 – 04 – 14 | 6 | 1/4″ | 04 | M14x1,5 | 8 | 4 | 21,5 | 10 | 14 |

| S104A0 – 04 – 16 | 6 | 1/4″ | 04 | M16x1,5 | 10 | 7 | 23,5 | 11 | 17 |

| S104A0 – 04 – 18 | 6 | 1/4″ | 04 | M18x1,5 | 12 | 9,5 | 23,5 | 11 | 19 |

| S104A0 – 05 – 16 | 8 | 5/16″ | 05 | M16x1,5 | 10 | 7 | 24 | 11 | 17 |

| S104A0 – 05 – 18 | 8 | 5/16″ | 05 | M18x1,5 | 12 | 9,5 | 24 | 11 | 19 |

| S104A0 – 06 – 16 | 10 | 3/8″ | 06 | M16x1,5 | 10 | 7 | 24,1 | 11 | 17 |

| S104A0 – 06 – 18 | 10 | 3/8″ | 06 | M18x1,5 | 12 | 9,5 | 24,6 | 11 | 19 |

| S104A0 – 06 – 22 | 10 | 3/8″ | 06 | M22x1,5 | 15 | 10 | 25,6 | 12 | 22 |

| S104A0 – 08 – 18 | 12 | 1/2″ | 08 | M18x1,5 | 12 | 9,3 | 24,8 | 11 | 19 |

| S104A0 – 08 – 22 | 12 | 1/2″ | 08 | M22x1,5 | 15 | 10 | 25,8 | 12 | 22 |

| S104A0 – 08 – 26 | 12 | 1/2″ | 08 | M26x1,5 | 18 | 12 | 26,3 | 12 | 27 |

| S104A0 – 10 – 26 | 16 | 5/8″ | 10 | M26x1,5 | 18 | 12 | 26,3 | 12 | 27 |

| S104A0 – 12 – 30 | 20 | 3/4″ | 12 | M30x2 | 22 | 15 | 29,5 | 14 | 30 |

| S104A0 – 16 – 36 | 25 | 1″ | 16 | M36x2 | 28 | 19,5 | 31,8 | 14 | 36 |

| S104A0 – 20 – 45 | 32 | 1.1/4″ | 20 | M45x2 | 35 | 26 | 39,5 | 16 | 46 |

| S104A0 – 24 – 52 | 40 | 1.1/2″ | 24 | M52x2 | 42 | 32 | 40,5 | 16 | 55 |

Product detail pictures:

Related Product Guide:

Importance of PVC Fittings

Understanding Hydraulic Hose Fittings

We always do the job to be a tangible group making sure that we can provide you with the top top quality as well as ideal value for 18 Years Factory offer 10411 Swaged Hose Fiting to Sevilla Factory, The product will supply to all over the world, such as: Greenland, Luxembourg, Maldives, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

Hozelock Superhoze Expandable Garden Hose

https://www.forhouseandhome.co.uk/specials/gift-themes/the-gardener/hozelock-superhoze-expandable-garden-hose/d121199

I have taught myself the basics of hydroponics and must have read every report and book on the subject. I have started out farming on the 100 square meter roof garden of my penthouse. After that I imported two models of rotating garden from Omega Gardens in Canada.. I was hooked.

This was a crazy project and I loved every moment of it. I have taught myself the basics of hydroponics and started farming on the roof of my penthouse. From there I progressed to rotating gardens and imported a machine from Omega Gardens in Canada.

The massive increases in the cost of electricity resulted in this project being canned. Valuable lessons were learned and I will most certainly try another improved version in the future. The explosive growth of lettuce in this environment was certainly amazing. This project was undertaken by two people. Frans Siditi , my African assistant and myself. A lot of blood, sweat and tears went into this. Thank you Frans- without your assistance this would not have been possible.

There was a nursery section where seedlings was kept at 9 cm centers and then moved to the grow out section with 22 cm centers. Harvesting commenced at 02h00 in the morning and the product was delivered at the market at 06h00. We used headlamps. LED headlamps sometimes have an infrared function as well. One night I have switched on the infrared function and looked at the plants. Generally you cannot see healthy plants. But if the leaves are burnt on the edges or have been damaged, then this is clearly visible. Amazing!! Making the holes took a very long time. Eventually we built is jig and used a drill press. A CNC machine will be better but will be too expensive. The floor of the greenhouse was sloped. I designed levelers and fitted them underneath the base of the A frame and then it was quite easy to adjust and to level the PVC pipes. Later on in the project we used a laser level and marked the spot for the nails. This was much quicker and more effective.

In another experiment I have used PVC safety netting and installed it vertically 2 meters high and suspended plastic beer cups against the net in rows. Plants in foamolite cups were inserted in the beer cups and drip fed from above. The results were equally impressive. The end of the PVC pipes were sealed off with 500 mm plastic beer cups collected from the cricket stadium after major matches. Several 2000 liter tanks were buried in the floor and each tank serviced 6 A-frame stacks ( one block) The base of the A-frame is 2 meters and the height 2.2 meters. This is slightly too high! Shorter people have difficulty in planting and harvesting at that height. Each pvc pipe has 13 holes. with 14 pvc pipes per growing station. The island distance between each growing station was 700mm. At the top ends the distance was 1500 mm between the different blocks.

How did I control the water level inside the growth pipe?

In the video, a lot of vertical down pipes can be seen. Each growth pipe had its own inflow ( 6mm sphagetti tubing) and at the other end its own outflow. The outflow down pipe also regulates the volume of the water inside the pipe. By pushing the down pipe up the volume of water is increased and by pushing it down, the volume of water is decreased.

At the bottom of the growth pipe, I have drilled a hole to accommodate a rubber grommet. Once fitted , a 20 mm PVC pipe will fit tightly into the grommet.

The plants were transplanted from the nursery into the out growing stations when the roots appeared on the bottom of the cup. At that stage the water must be higher in the growth pipe. As the root mass increase in length, the water level will be reduced by moving the down pipes down ward.

If you like this, please subscribe to the Channel. Please inform your friends about this by sending this tweet to them:

https://clicktotweet.com/k749U

If you want access to my project pictures, please write to me and request access to my folders stored online which contain more than 500 pictures as well as a huge database or related research done by me.

Sources of reference:

Dudley Harris = Hydroponics- The complete guide to gardening without soil

Howard Resh = Hydroponic Food Production

Nic JJ Combrinck= Nutrient Solutions and Greenhouse Management

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!