13 Years Factory wholesale JAPANESE METRIC FEMALE KOMATSU TYPE (CRIMPED – BACK NUT) Swaged Hose Fiting for kazakhstan Manufacturers

13 Years Factory wholesale JAPANESE METRIC FEMALE KOMATSU TYPE (CRIMPED – BACK NUT) Swaged Hose Fiting for kazakhstan Manufacturers Detail:

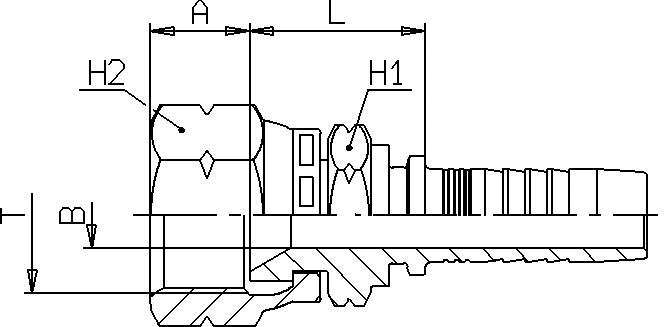

JAPANESE METRIC FEMALE KOMATSU TYPE (CRIMPED – BACK NUT)

|

PART NUMBER |

HOSE

|

THREAD T |

|

B mm |

L mm |

A mm |

H1 mm |

H2 mm |

||

|

|

DN |

In |

SIZE |

|

|

|

|

|

|

|

| S286A3 – 04 – 14D | 6 | 1/4″ | 04 | M14x1,5 | 4 | 23 | 10,5 | 17 | 19 | |

| S286A3 – 05 – 16D | 8 | 5/16″ | 05 | M16x1,5 | 5,5 | 22,5 | 9,3 | 19 | 21 | |

| S286A3 – 06 – 18D | 10 | 3/8″ | 06 | M18x1,5 | 7 | 23,6 | 11,5 | 19 | 24 | |

| S286A3 – 08 – 22D | 12 | 1/2″ | 08 | M22x1,5 | 9,3 | 24,8 | 14 | 22 | 27 | |

| S286A3 – 10 – 24D | 16 | 5/8″ | 10 | M24x1,5 | 12 | 26,8 | 15,1 | 30 | 32 | |

| S286A3 – 12 – 30D | 20 | 3/4″ | 12 | M30x1,5 | 15 | 31,5 | 18,3 | 32 | 36 | |

| S286A3 – 16 – 33D | 25 | 1″ | 16 | M33x1,5 | 19,5 | 33,3 | 21,3 | 36 | 41 | |

Product detail pictures:

Related Product Guide:

Understanding Hydraulic Hose Fittings

Things to Know About Pipe Fitting Works

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for 13 Years Factory wholesale JAPANESE METRIC FEMALE KOMATSU TYPE (CRIMPED – BACK NUT) Swaged Hose Fiting for kazakhstan Manufacturers, The product will supply to all over the world, such as: Kyrgyzstan, Turin, Paraguay, We are confident that we are able to provide you with opportunities and will be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of products that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.